As described in the page for the structure of the whole project, the Running Shed is being built in seven phases. The first two phases are now complete, and have involved obtaining planning permissions and then constructing a pit between the rails that will be in the shed. This pit is now finished and the tracks have been replaced, and locomotive crews and maintenance volunteers have been taking full advantage of the increased space.

The picture below shows a panoramic view of the pit, with the crane stabled on it. Do not believe that the camera never lies - the pit and the track on which the crane is standing really are straight!

During the construction a lot of materials were used, including over 700 blocks. As illustrated in the page for the construction of the pit, all of this work, including laying all of these blocks, was completed by our volunteers, so as always a big "thank you" to them for the work that they were able to do. As well as building the pit, the feed pipe to the water tower was placed in a duct and buried, making servicing of the pipe, or even its future replacement, much easier. These works did take slightly longer to complete than we had hoped, but as is often the case with track work and civil engineering, it’s the fine tuning that takes the time to get right.

Design

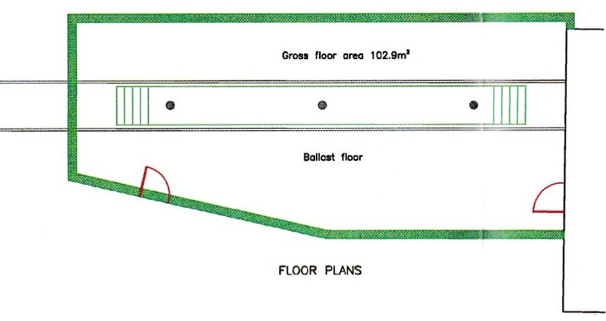

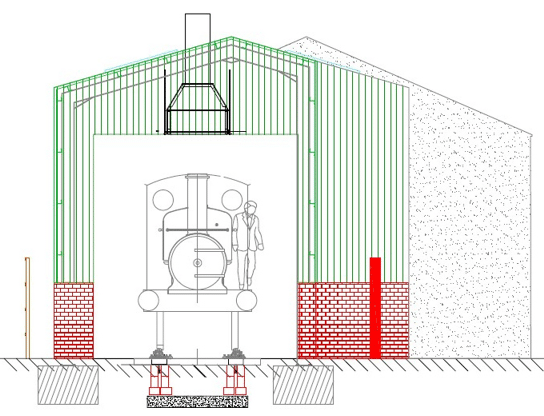

Phase 3 of the project was then mainly concerned with finalising the detailed design of the Running Shed, and negotiating with the contractors who had been appointed to manufacture the steel framing of the building and the cladding sheets, and also to carry out much of the construction work. The plan and south elevation of the running shed are shown below, along with a picture of one of our locomotives standing in the location of the one shown in the elevation.

Plan of the running shed. Unlike many plans, north is to the right of this one, and south to the left.

South elevation of the Running Shed (ie looking from left to right in the plan above).

A diesel locomotive standing on the site of the Running Shed, with a crane standing behind it. They are in the same position as the steam locomotive illustrated in the elevation above.

Picture © Tony Cowling, 2016.

Site Preparation

The other main part of the work in this phase was to prepare the site ready for phase 4. During February 2016 a bit more work was done on the pit, to construct the two sets of steps that will separate the external part of the pit from the part inside the running shed.

Work in progress during February 2016 on the construction of the two sets of steps that will separate the external part of the pit (nearest the camera) from the part that will be inside the running shed.

Picture © Tony Cowling, 2016.

Another part of this site preparation was that during the construction work itself the pit needed to be covered over, to avoid any risk of people working on the construction falling into it. Timber covers were therefore fabricated for this purpose, which each needed to be solid enough to support the weight of at least one person.

Some of the timber covers for the pit, leaning against the wall of the Engine House.

Picture © Tony Cowling, 2016.

Next Steps

The next part of the actual building work was phases 4, 5 and 6 of the project. Phase 4 consisted of excavating for and then constructing the foundations of the building, and a separate page for phase 4 describes the details of the work done for this. This phase also included installing the drainage system, and in particular an oil separator and pump. Although it is not obvious in the pictures of the pit above, it has a drainage channel set into the concrete base, which we are pleased to report works excellently, and this was connected to the oil separator when it had been installed.

As soon as the foundations were constructed then phases 5 and 6 followed immediately. Phase 5 was the erection of the steel frame for the building, which only took a week, and then phase 6 would involve the contractors fitting the steel cladding sheets to it, and our volunteers laying lots of bricks.

Go on to the next stage in this project.

Go back to the previous stage in this project.

Return to the overall description of this project.

More Information

Other pages about this project and the "Buy a Brick" appeal:

- An overview of the project and the appeal;

- The "Buy a Brick" appeal;

- The structure of the project;

- The progress with the project;

- The construction of the pit;

- Construction of the foundations;

- Erection of the framework;

- Construction of the walls;

- Fitting out;

- The opening ceremony.

Other pages provide more information about: