Projects

Buy a Brick

Helping with funding

The running shed project is a big one, and unlike previous building projects that we have undertaken there is currently no grant aid for which it would be eligible, so that we need to raise the funds for it ourselves. Even doing much of the work using our own volunteer labour, we initially estimated that we would need to raise at least £46,000 to build the Running Shed, to cover materials and the parts of the work for which we have to employ contractors.

Since then, costs have risen a bit, partly because some further bits of the work have been identified where contractors will be needed, so that we currently estimate the total cost of the project as just under £49,000. Of course, it would be nice if we could simply pay contractors to do all of the building work, but that would be even more expensive!

The fundraising appeal has now closed, so the material below about buying bricks no longer applies. But, the building is not yet finished, and so there is still scope for you to help the project by volunteering: details of this are given below.

You can help us by buying a brick at £2.50 each, and there are three ways in which you can do this:

- in person at our shop;

- by completing the donation form which can be accessed by clicking here (and will open in a new browser tab or window), and then returning this to us at: The Station, Moor Road, Hunslet, Leeds, LS10 2JQ; or

- if you are buying a number of bricks, or are buying a brick and want to have it engraved (as described below), then we can take the details by telephone (0113 271 0320), and accept payment by credit or debit card. We accept most payment cards (except American Express & Diners Card), but only for payments of more than £5.

The "brickometer" currently stands at over £18,000, which is a magnificent result, but even so we still need more!

A Name Engraved on a Brick

Another possibility which was available was to have a name engraved on a brick which will be used in the construction of the running shed. This possibility has now closed, as the last batch of bricks has had to be sent off for engraving in order for us to get them back in time to be used.

These bricks will be placed in a prominent position on the Running Shed wall. Great idea for yourself, a present or in memory of someone. But the last batch of bricks has now been sent away to be engraved, so as to ensure that they are back ready to be used in time for when bricklaying will start.

The first batch of bricks were engraved last year, and if you have ordered a brick that is in this first batch then you can view it in the shop. The picture below shows this first batch of engraved bricks, when it had been collected from the engravers in Birmingham by one of our volunteers.

Helping by volunteering

We are always happy to receive offers from anybody to contribute as a volunteer to the work of the railway. If you have particular skills that might be useful in this project then we will be particularly happy to hear from you, but don't be put off from offering if you haven't. Running the railway involves all sorts of tasks, and many of our volunteers contribute to all sorts of these. So, if you can help with some other activity, then it may free up others to put more time into this project.

Also, because the railway is run entirely by volunteers, we are very well aware of the importance of training, particularly given the historic nature of many of the technologies that we use. So, even if you do not have any particular skill that would be needed for this project, if you are willing to learn then we will be happy to try to train you.

Separate pages give more details about becoming a member of the railway and about contributing as a volunteer to any of the aspects of the work of the railway.

Following the project

To help inform subscribers to the appeal of the progress with the Running Shed project, we produced a newsletter at the beginning of March 2016 and sent this out to all donors for whom we had addresses recorded. A copy of this can be accessed by clicking this link - but it is a large file (3.2MB), and so may take a little while to download.

Also, you will be able to follow the progress of the work on the Running Shed by checking back regularly on this website. Since we are all volunteers, however, we can't promise to keep it updated in real-time! Or, you are welcome to visit the railway when it is open and ask whether you can see the progress - although this may not always be possible for safety reasons, since the site of the project is next to an area where trains may be operating.

If you have any questions about the Running Shed, or would like to discuss further sponsorship opportunities, please contact one of our volunteer team at the railway or e-mail

Go on to the next stage in this project.

Return to the overall description of this project.

More Information

Other pages about this project and the "Buy a Brick" appeal:

- An overview of the project and the appeal;

- The structure of the project;

- The progress with the project;

- The construction of the pit;

- Design and site preparation;

- Construction of the foundations;

- Erection of the framework;

- Construction of the walls;

- Fitting out;

- The opening ceremony.

Other pages provide more information about:

Overhaul of "Brookes No. 1"

As part of a successful Heritage Lottery Fund bid, the Middleton Railway has embarked on a project to restore to working order Brookes No. 1 (Hunslet 2387 of 1941), illustrated below. This locomotive has seen service on the Middleton Railway in the last decade as both a ‘Thomas’ and in its authentic guise as a saddle tank.

As part of a successful Heritage Lottery Fund bid, the Middleton Railway has embarked on a project to restore to working order Brookes No. 1 (Hunslet 2387 of 1941), illustrated below. This locomotive has seen service on the Middleton Railway in the last decade as both a ‘Thomas’ and in its authentic guise as a saddle tank.

This locomotive forms an important part of the Leeds locomotive building story and our history, having been built less than a mile from the railway. Furthermore, it is the only surviving locomotive of its class (ie with 14" diameter cylinders), although there are a number of survivors of the larger versions (ie with 15", 16" or 18" diameter cylinders). We hoped to see her return to traffic by 2017, and this was finally achieved at the end of August 2017 (on the Bank Holiday Monday). These pages tell the story of her overhaul.

Our bid to the Heritage Lottery Fund was for a grant to acquire this locomotive, and also Picton (Hunslet 1540 of 1927), together with an archive of papers relating to them, and then to conserve both of the locomotives. They had both previously been owned by David Monckton, who was a former chairman of the Middleton Railway Trust, and also the architect who had designed our Engine House building. In the case of Brookes No. 1, conservation meant an overhaul to return it to working order: it would have been nice if we could have done the same for Picton, but sadly that is not a realistic option.

Initial inspection carried out during the preparation of the bid suggested that the boiler should need relatively little work, as it was new at the start of the locomotive's last "10 year ticket" in 1999. On the other hand, we could not rule out the possibility that some repairs to the boiler shell might turn out to be needed, and so a special contingency had to be included in the project plan to cover this possibility.

Consequently, the main focus of the overhaul would be on the chassis, which was known to need considerable work in many areas, including the expensive possibilities that we might find we needed to fit cylinder liners or re-face the slide valves. The part of the overall project plan for the overhaul, as this was included in the bid, therefore identified the following 13 steps, plus a general contingency to allow for parts of the work taking longer than we expected.

- Remove tank, cab, boiler cladding and fittings, lift boiler out of frames.

- Lift frames off wheels, remove running gear and motion.

- Remove old tubes from boiler, prepare for statutory inspections and determine whether any special repairs are required.

- Carry out ultrasonic tests and other statutory inspections.

- Special contingency – carry out repairs to the boiler shell if they are needed.

- Overhaul running gear, motion and frames, repaint as necessary.

- Overhaul cylinders, pistons and valves.

- Special contingency – fit cylinder liners if they are needed.

- Special contingency – re-face valves if they need it.

- Refit running gear and motion, refit frames onto wheels.

- Fit new boiler tubes, make new ashpan and carry out other general work on the boiler and piping.

- Lift boiler back into frames, replace tank, cab, boiler cladding and fittings.

- Finish repainting.

Another of the main aims of the project was to develop the skills of our younger volunteers, so as to leave a lasting legacy for the future of the Middleton Railway. As such, two other important parts of the overall project plan were firstly that we should document and interpret the work being done during the overhaul; and secondly that in carrying out these various steps of the work we should arrange to instruct any of our younger volunteers in the methods that were needed.

In practice, as the project progressed it rapidly became apparent that we needed to be quite flexible in interpreting "younger volunteers" simply as "volunteers with limited experience", since many of our not-so-young volunteers turned out to have plenty to learn, too. Thus, the various Mutual Improvement Classes and other training activities that were run in conjunction with this project actually involved instructing many of our volunteers in methods that were not already familiar to them.

The other pages that describe this project then illustrate the actual work that was done, although they do not need to break it down into the 13 steps listed above. Rather, the actual work of the overhaul splits into three main phases, as follows.

- Initial dismantling, which was carried out in the open air.

- Work done in the workshop, with the frames lifted off the wheels.

- Work done once the frames were back on the wheels, including re-fitting the boiler and re-assembly, and finishing up with the return to service.

Go on to the first phase of this project.

More Information

Pages about other projects:

- Last Coals to Leeds;

- Raising Steam in No. 6;

- Project Phoenix;

- Building a Running Shed;

- Conserving "Picton".

Other pages provide more information about:

"Brookes No. 1" Overhaul Phase 1

As explained in the main page for the project, this first phase of the overhaul of Brookes No. 1 (Hunslet 2387 of 1941) consisted of those parts of the work that could be carried out while waiting for space in the workshop to become available.

As explained in the main page for the project, this first phase of the overhaul of Brookes No. 1 (Hunslet 2387 of 1941) consisted of those parts of the work that could be carried out while waiting for space in the workshop to become available.

Click on the links below to track our progress during this phase:

April 2013

In April 2013 we began the process of dismantling Brookes No.1. In line with our promise to encourage our younger members to be involved in the work we let them get on with many of the jobs. The controls in the cab were removed as far as possible and put into storage. Then the external fittings holding the saddle tank such as the whistle, safety valves and injector pipework were removed. When the tank was ready to come off the loco was moved outside. A crane was used to lift the tank away and it was put into storage until the locomotive would be ready to receive it once again in a couple of years time.

May 2013

The next stage in dismantling Brookes was to remove the boiler lagging. First, the steel sheet cladding was removed, then the lagging. The locomotive was originally built in 1941, and at that time the lagging would have been asbestos. Now that the dangers of asbestos have been recognised, we use a glass or a ceramic fibre.

Once the lagging had been removed the boiler was in its 'naked' state and twenty or more wash-out and inspection plugs had to be removed. The boiler then had its final fittings removed, received a good clean down and was lifted from the frames for storage outside.

June 2013

The rather large task of removing the 150+ tubes from the boiler was completed in the rest of May and into June. This involved grinding off the 'bead' in the firebox end (designed to stop the tubes burning away while in use) and hammering them out. The tubes were then cut off at the smokebox end, hammered back into the boiler and fished out through a specially enlarged tube hole at the bottom of the front tubeplate. This operation was hot, loud and above all hard work, taking several weekends to complete. This was not the only reason why the younger volunteers were asked to get involved, though!

Once all of the tubes had been removed, the boiler inspector could examine the boiler properly, and carry out the ultrasonic tests to find out whether any repairs to the boiler shell would be needed. The outcome of this was that the boiler was given a clean bill of health, and so one of the special contingencies for which we had needed to make allowance in planning the project could be eliminated, which was definitely good news.

Summer 2013

A start could now be made on the bottom end of the locomotive (ie its frames and motion), where a considerable amount of work was needed. We first had to remove all of the peripheral parts such as coupling and connecting rods, brake gear and the horn stays, and all the parts removed put into safe storage. Once this had been done, it would be possible to lift the locomotive up off its wheels, in order to assess the extent of 'wear and tear' on it, but this step would have to wait until there was space available in the workshop. The next two pictures show the frames before and after the removal of the coupling rods.

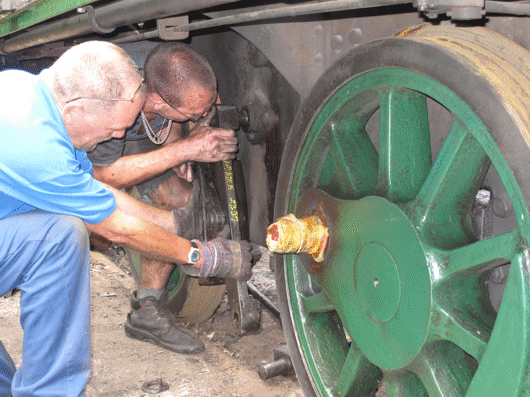

With the coupling rods out of the way, the next step was to remove the brake blocks from the hangers, and then the brake hangers from their pivots, as shown below. Meanwhile, between the frames, the rest of the motion could be removed piece by piece, although some of the bolts holding them together needed a lot of persuasion to come undone - hence the assortment of tools in the picture.

Once these parts had all been removed, work stopped for a while during the winter: trying to dismantle steam locomotives out of doors in rain or snow is not conducive to doing a good job. So, volunteer efforts were redirected to other projects, to prepare for the start of the 2014 operating season.

Summer 2014

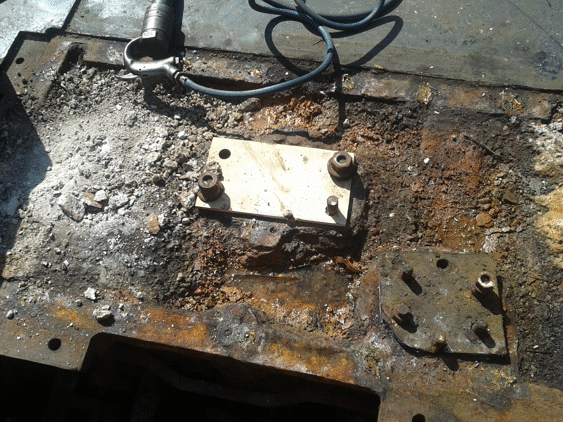

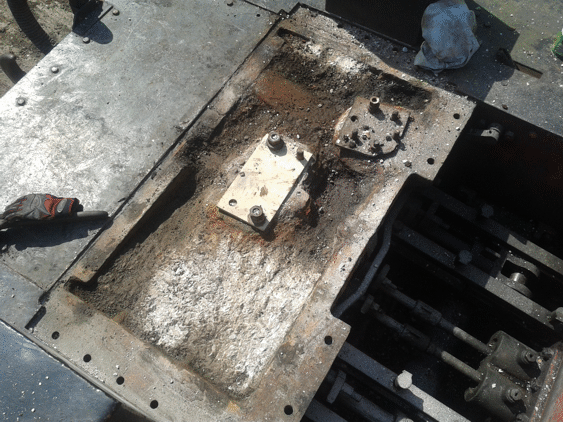

Once we had better weather work could resume, but there was now not a lot more that could be done until the frames could be moved into the workshop. One job that was done, however, was to renew the concrete that covers the cylinder block to form the floor of the smokebox. The pictures below show the corroded state of the old concrete, and then the top of the cylinder block once the old concrete had been removed, and finally the new concrete in place. Notice the cover plates that have been fitted to the flanges for the main steam pipe into the cylinders (the smaller one on the right in the first picture) and for the exhaust pipe from the cylinders (in the centre).

Our young (and some not-so-young) volunteers continued to do what work was possible on this project, but progress was more-or-less halted until the frames could be moved into the workshop for the next phase of the work. After having had a hard life in industry and as a 'Thomas' loco on hire, we knew that this next phase was likely to involve a lot of work on re-pinning, bushing and replacing parts of the locomotive. We had even had to put special contingencies into the budget for re-boring and fitting liners to the cylinder block if necessary, and also for re-facing the valves. If either of these turned out to be needed then some exciting engineering was likely to be involved.

Go on to the next stage in this project.

Return to the overall description of this project.

More Information

Other pages about this project:

Other pages provide more information about: