General

Overhaul of "Brookes No. 1"

As part of a successful Heritage Lottery Fund bid, the Middleton Railway has embarked on a project to restore to working order Brookes No. 1 (Hunslet 2387 of 1941), illustrated below. This locomotive has seen service on the Middleton Railway in the last decade as both a ‘Thomas’ and in its authentic guise as a saddle tank.

As part of a successful Heritage Lottery Fund bid, the Middleton Railway has embarked on a project to restore to working order Brookes No. 1 (Hunslet 2387 of 1941), illustrated below. This locomotive has seen service on the Middleton Railway in the last decade as both a ‘Thomas’ and in its authentic guise as a saddle tank.

This locomotive forms an important part of the Leeds locomotive building story and our history, having been built less than a mile from the railway. Furthermore, it is the only surviving locomotive of its class (ie with 14" diameter cylinders), although there are a number of survivors of the larger versions (ie with 15", 16" or 18" diameter cylinders). We hoped to see her return to traffic by 2017, and this was finally achieved at the end of August 2017 (on the Bank Holiday Monday). These pages tell the story of her overhaul.

Our bid to the Heritage Lottery Fund was for a grant to acquire this locomotive, and also Picton (Hunslet 1540 of 1927), together with an archive of papers relating to them, and then to conserve both of the locomotives. They had both previously been owned by David Monckton, who was a former chairman of the Middleton Railway Trust, and also the architect who had designed our Engine House building. In the case of Brookes No. 1, conservation meant an overhaul to return it to working order: it would have been nice if we could have done the same for Picton, but sadly that is not a realistic option.

Initial inspection carried out during the preparation of the bid suggested that the boiler should need relatively little work, as it was new at the start of the locomotive's last "10 year ticket" in 1999. On the other hand, we could not rule out the possibility that some repairs to the boiler shell might turn out to be needed, and so a special contingency had to be included in the project plan to cover this possibility.

Consequently, the main focus of the overhaul would be on the chassis, which was known to need considerable work in many areas, including the expensive possibilities that we might find we needed to fit cylinder liners or re-face the slide valves. The part of the overall project plan for the overhaul, as this was included in the bid, therefore identified the following 13 steps, plus a general contingency to allow for parts of the work taking longer than we expected.

- Remove tank, cab, boiler cladding and fittings, lift boiler out of frames.

- Lift frames off wheels, remove running gear and motion.

- Remove old tubes from boiler, prepare for statutory inspections and determine whether any special repairs are required.

- Carry out ultrasonic tests and other statutory inspections.

- Special contingency – carry out repairs to the boiler shell if they are needed.

- Overhaul running gear, motion and frames, repaint as necessary.

- Overhaul cylinders, pistons and valves.

- Special contingency – fit cylinder liners if they are needed.

- Special contingency – re-face valves if they need it.

- Refit running gear and motion, refit frames onto wheels.

- Fit new boiler tubes, make new ashpan and carry out other general work on the boiler and piping.

- Lift boiler back into frames, replace tank, cab, boiler cladding and fittings.

- Finish repainting.

Another of the main aims of the project was to develop the skills of our younger volunteers, so as to leave a lasting legacy for the future of the Middleton Railway. As such, two other important parts of the overall project plan were firstly that we should document and interpret the work being done during the overhaul; and secondly that in carrying out these various steps of the work we should arrange to instruct any of our younger volunteers in the methods that were needed.

In practice, as the project progressed it rapidly became apparent that we needed to be quite flexible in interpreting "younger volunteers" simply as "volunteers with limited experience", since many of our not-so-young volunteers turned out to have plenty to learn, too. Thus, the various Mutual Improvement Classes and other training activities that were run in conjunction with this project actually involved instructing many of our volunteers in methods that were not already familiar to them.

The other pages that describe this project then illustrate the actual work that was done, although they do not need to break it down into the 13 steps listed above. Rather, the actual work of the overhaul splits into three main phases, as follows.

- Initial dismantling, which was carried out in the open air.

- Work done in the workshop, with the frames lifted off the wheels.

- Work done once the frames were back on the wheels, including re-fitting the boiler and re-assembly, and finishing up with the return to service.

Go on to the first phase of this project.

More Information

Pages about other projects:

- Last Coals to Leeds;

- Raising Steam in No. 6;

- Project Phoenix;

- Building a Running Shed;

- Conserving "Picton".

Other pages provide more information about:

"Brookes No. 1" Overhaul Phase 1

As explained in the main page for the project, this first phase of the overhaul of Brookes No. 1 (Hunslet 2387 of 1941) consisted of those parts of the work that could be carried out while waiting for space in the workshop to become available.

As explained in the main page for the project, this first phase of the overhaul of Brookes No. 1 (Hunslet 2387 of 1941) consisted of those parts of the work that could be carried out while waiting for space in the workshop to become available.

Click on the links below to track our progress during this phase:

April 2013

In April 2013 we began the process of dismantling Brookes No.1. In line with our promise to encourage our younger members to be involved in the work we let them get on with many of the jobs. The controls in the cab were removed as far as possible and put into storage. Then the external fittings holding the saddle tank such as the whistle, safety valves and injector pipework were removed. When the tank was ready to come off the loco was moved outside. A crane was used to lift the tank away and it was put into storage until the locomotive would be ready to receive it once again in a couple of years time.

May 2013

The next stage in dismantling Brookes was to remove the boiler lagging. First, the steel sheet cladding was removed, then the lagging. The locomotive was originally built in 1941, and at that time the lagging would have been asbestos. Now that the dangers of asbestos have been recognised, we use a glass or a ceramic fibre.

Once the lagging had been removed the boiler was in its 'naked' state and twenty or more wash-out and inspection plugs had to be removed. The boiler then had its final fittings removed, received a good clean down and was lifted from the frames for storage outside.

June 2013

The rather large task of removing the 150+ tubes from the boiler was completed in the rest of May and into June. This involved grinding off the 'bead' in the firebox end (designed to stop the tubes burning away while in use) and hammering them out. The tubes were then cut off at the smokebox end, hammered back into the boiler and fished out through a specially enlarged tube hole at the bottom of the front tubeplate. This operation was hot, loud and above all hard work, taking several weekends to complete. This was not the only reason why the younger volunteers were asked to get involved, though!

Once all of the tubes had been removed, the boiler inspector could examine the boiler properly, and carry out the ultrasonic tests to find out whether any repairs to the boiler shell would be needed. The outcome of this was that the boiler was given a clean bill of health, and so one of the special contingencies for which we had needed to make allowance in planning the project could be eliminated, which was definitely good news.

Summer 2013

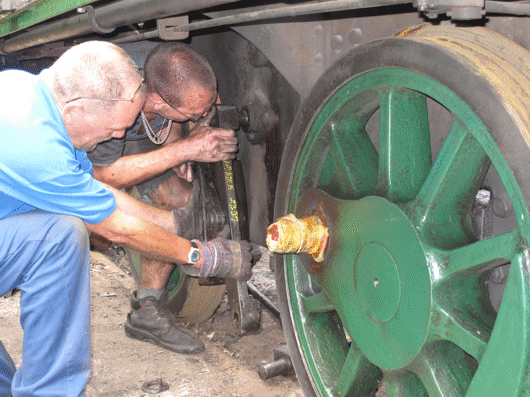

A start could now be made on the bottom end of the locomotive (ie its frames and motion), where a considerable amount of work was needed. We first had to remove all of the peripheral parts such as coupling and connecting rods, brake gear and the horn stays, and all the parts removed put into safe storage. Once this had been done, it would be possible to lift the locomotive up off its wheels, in order to assess the extent of 'wear and tear' on it, but this step would have to wait until there was space available in the workshop. The next two pictures show the frames before and after the removal of the coupling rods.

With the coupling rods out of the way, the next step was to remove the brake blocks from the hangers, and then the brake hangers from their pivots, as shown below. Meanwhile, between the frames, the rest of the motion could be removed piece by piece, although some of the bolts holding them together needed a lot of persuasion to come undone - hence the assortment of tools in the picture.

Once these parts had all been removed, work stopped for a while during the winter: trying to dismantle steam locomotives out of doors in rain or snow is not conducive to doing a good job. So, volunteer efforts were redirected to other projects, to prepare for the start of the 2014 operating season.

Summer 2014

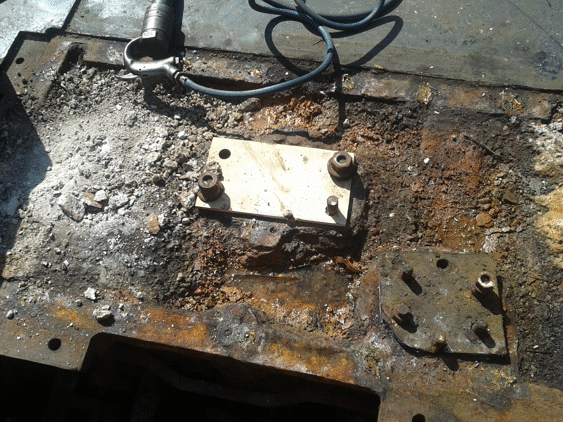

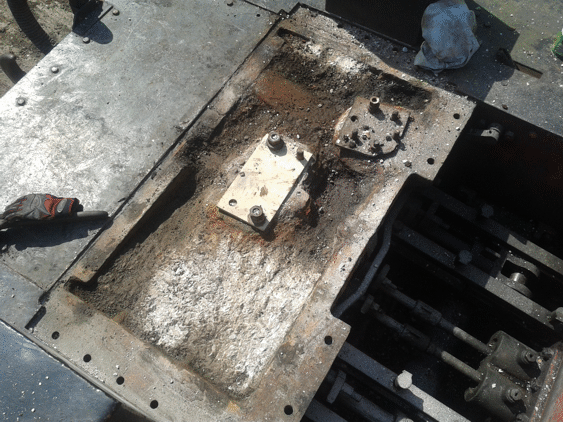

Once we had better weather work could resume, but there was now not a lot more that could be done until the frames could be moved into the workshop. One job that was done, however, was to renew the concrete that covers the cylinder block to form the floor of the smokebox. The pictures below show the corroded state of the old concrete, and then the top of the cylinder block once the old concrete had been removed, and finally the new concrete in place. Notice the cover plates that have been fitted to the flanges for the main steam pipe into the cylinders (the smaller one on the right in the first picture) and for the exhaust pipe from the cylinders (in the centre).

Our young (and some not-so-young) volunteers continued to do what work was possible on this project, but progress was more-or-less halted until the frames could be moved into the workshop for the next phase of the work. After having had a hard life in industry and as a 'Thomas' loco on hire, we knew that this next phase was likely to involve a lot of work on re-pinning, bushing and replacing parts of the locomotive. We had even had to put special contingencies into the budget for re-boring and fitting liners to the cylinder block if necessary, and also for re-facing the valves. If either of these turned out to be needed then some exciting engineering was likely to be involved.

Go on to the next stage in this project.

Return to the overall description of this project.

More Information

Other pages about this project:

Other pages provide more information about:

Little Railway, Big History

1758

The Middleton Colliery Railway made history right from the start. To protect its route, the land- and coal-owner Charles Brandling secured an Act of Parliament: the very first Act titled for, and largely concerned with, the building of a waggonway or railway.

An extract from a 1758 newspaper, reporting the first loads moved over the waggonway

From its opening in September 1758, horses pulled thousands of tons of coal a year down the waggonway to Leeds. Cheaper coal prices, based on more efficient transport, gave Leeds a head start in the newly developing large-scale industries. Our city became an important centre for all industries using coal as a source of heat or power: metal-working, brick, glass, pottery and tile manufacture, brewing, dyeing, and clothmaking in steam-powered mills.

1812

Fifty years later however, the colliery was having to compete with the Army for the purchase of work-horses and fodder, as the Duke of Wellington pursued Napoleon Bonaparte around Europe. As horses and fodder became scarcer, prices rose at home.

Estate and colliery steward, John Blenkinsop, substantially reduced Middleton’s transport costs by introducing steam locomotives. The very few locomotives built so far had largely failed because only cast iron rails were available. These broke easily under the impact of any machine large enough to haul a viable load. A locomotive not able to haul a viable load was of little use.

Blenkinsop invented a rack and pinion system, very similar to that still used on many mountain railways. A large rack wheel at one side of the locomotive connected with cogs cast into the rail at that side, giving substantial assistance to the locomotive’s pulling power without needing to be heavy enough to break its track.

The four locomotives built for the colliery by Matthew Murray, designed by him to incorporate John Blenkinsop’s patented rack wheel, were the world’s first commercially viable locomotives.

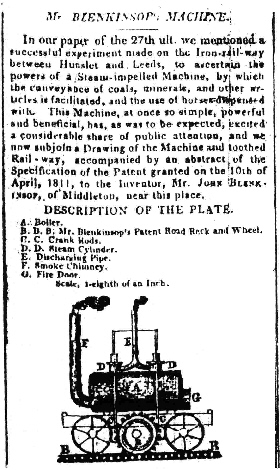

An extract from an 1812 newspaper, illustrating the Murray-Blenkinsop locomotives

The Middleton Railway immediately began to attract visitors from all over the world, as well as from the UK. They included two new categories of traveller: the techno-tourist and the industrial spy!

Many foreign visitors tried to interest their own governments and industrialists in the idea of introducing locomotive-worked railways. In 1815, the technical design was published in a French science and industry journal, and within the next few years the Prussian government had two locomotives built in Berlin to the Murray-Blenkinsop design: the first locomotives ever constructed on mainland Europe. Neither of them proved to be successful: one ended its days as a stationary pumping engine, and the other, after a year or so powering a confectioner’s flour mill, was sold to an earthernware works. The rack wheel and a few other fragments of the latter machine were displayed in a Saarland farmer’s barn for many years.

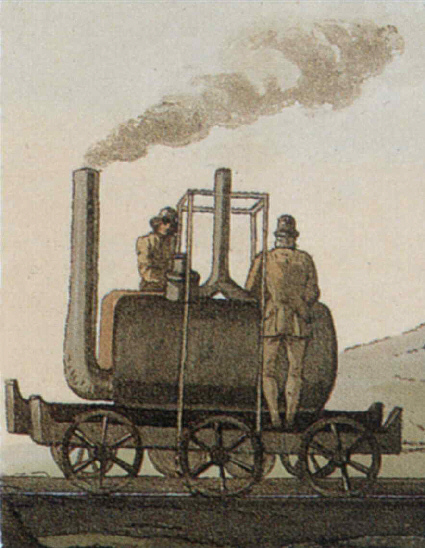

A contemporary painting of one of the Murray-Blenkinsop locomotives

After the last of the four Middleton locomotives wheezed to a final halt in 1835, after at least 20 years of unremitting hard work, there followed 125 years of comparative obscurity, whilst the railway faithfully continued to keep the growing industrial city supplied with coal.

c.1830-1995

However, Leeds had now profited in a new way from the presence of the Middleton Railway. The building of its four pioneer locomotives, plus at least two others built for the Kenton & Coxlodge waggonway at Newcastle, had resulted in a number of Leeds engineers having experience in locomotive design and construction, and when steam railways began to spread across the country, Leeds was well-prepared to begin manufacturing their locomotives.

Remains of the Railway Foundry, one of the earliest engine works in Hunslet

The firms clustered around Jack Lane, Hunslet, supplied locomotives and other railway equipment to almost every country in the world (well, a few countries never had railways!).

The Manning Wardle offices on Jack Lane

The Hunslet Engine Company offices on Jack Lane

1960

In 1960, the Middleton Colliery Railway was back in the news. Its coal traffic having been severely curtailed by its current owners the National Coal Board, part of the track was purchased by a neighbouring company, Clayton’s, who allowed the Middleton Railway Preservation Society to begin running goods traffic for them. The society (later to become the Middleton Railway Trust) had been started by staff and students of Leeds University, led by lecturer Dr. Fred Youell.

A goods train in the early 1960s

From 1960 until 1983, the society moved many thousands of tons of fabricated and scrap metal between Balm Road Goods Yard and Claytons and their neighbours Robinson & Birdsell. However, the society’s rail traffic movements started with several days of passenger train services as part of the 1960 University Rag Week: the first passenger services ever to be run on a standard gauge railway by a completely volunteer operated society.

One of the first trains for the University Rag Week in 1960

In 1969, as goods traffic began to decline, passenger services ‘resumed’ on a regular basis, and have continued since then, running every weekend and Bank Holiday Monday for a large part of the year.

Around 1975, we ran the first of our annual special trains for visiting school classes.

1983

In 1983, our benefactors Clayton’s closed down their Dartmouth Works site, where our society had been allowed to make its home, and we had to move all our equipment and vehicles to our current home site. New tracks were laid to accommodate the vehicle collection, and a workshop and a ticket office/shop were also built.

The eventual site of our station as it was in 1960

Roughly the same view in 1983

And a similar view in 2008

The inside of our Moor Road shop as it was in the 1980s and 1990s

In recent years, a superb new visitor centre has been constructed, to display and interpret the Middleton Railway’s history and its interesting collection of small, mainly industrial locomotives, a substantial percentage of which were built nearby in Jack Lane.

The Engine House Display Hall

2008

The railway celebrated its 250th Anniversary.

2010

We celebrated our society’s 50th Anniversary.

2012

We celebrated the 200th Anniversary of the first commercially viable locomotive, Middleton’s Murray-Blenkinsop locomotive ‘Salamanca’.

Little Railway – Amazing History!

For much more information, see our illustrated 68-page History of the Middleton Railway Leeds, which is available from the Railway’s shop. More details of this book are given on the separate page describing the books that we have for sale.

Return to the page for our museum collection.

More Information

Other pages provide more information about:

Enthusiasts

As well as being a popular family attraction we have plenty to interest railway enthusiasts as well as anyone interested local and industrial history. We have a museum at our Hunslet Moor Road site, the 'Engine House', dedicated to our local engine making heritage and our historic line.

For our 2009 diesel gala we had a visiting Hunslet built 'Class 05' shunter, shown in the picture below. This was quite a celebration of the locally made shunters with three examples proudly bearing the Hunslet name working passenger and demonstration freight trains in the Hunslet area itself, as well as our own collection of Hudswell, Clarke & Co engines.

Our Line

The now picturesque woodland of Middleton Park was once a hive of industry. Coal was initially extracted from pits that were little more than holes in the ground. Later horses were used to wind baskets of coal up by rope and later still steam engines were used to wind larger volumes of coal from beneath the ground. To this day remains of these early coal workings can still be seen in Middleton Park and it is worth stopping off at Park Halt for a visit.

Middleton is however over two miles from the centre of Leeds. Early waggonways had been built at Middleton and in 1758 the first act of parliament for the construction of a railway was granted to formally establish this important route in to Leeds. In 1812 the railway achieved another first, being the first line to successfully employ steam locomotives. Another first in 1960 saw the line become the first standard gauge railway to be taken over by railway enthusiast volunteers. Click on the link in the menu to read more about our history.

Our Engines

We have a large and varied collection of industrial locomotives dating from 1890 to 1980. Many of our locomotives were built by the local works in Hunslet a short distance from our Engine House. Click on the link in the menu to read more about our locos and stock.

Leeds Engine Making

The Middleton Railway has always been closely linked to the local engine making industry. The first series of industrial locomotives in the world were built in Leeds for use on our line. In Victorian times the line was re-equipped with engines from Manning Wardle, a manufacturer that is well represented in our operating fleet today. The line was also used on a number of occasions to test new locos.

New John Fowler diesel shunter 4230001 on test on the Middleton Railway in the 1960s

Photo © Sheila Bye

Leeds was the biggest locomotive building city in England, even beating the well known locomotive building cities such as Swindon, Crewe and Doncaster. The reason this fact is a surprise to many is that nearly all of the locomotives built in Leeds were for industrial use or export.

Much more about this important part of our local history can be discovered in our Engine House. Since you are most likely sat in front of a computer or some such gadget on the internet right now you can learn about our local engine builders from the dedicated site www.leedsengine.info.

www.leedsengine.info contains histories of the Leeds engine making firms, details of what sights can still be seen around Leeds today and details of the books available on the subject. The site also has a database under construction that hopefully will eventually list all the 20,000+ engines built in Leeds, this database is most of the way there already.

Off The Rails

Local works also had a dominant position in the worldwide supply of all sorts of other steam powered machinery. Information on these products is also available on the www.leedsengine.info site. We also have good links with local owners of traction engines, steam rollers and steam lorries, and they often bring some of their vehicles along to our special events. The picture below shows John Fowler steam roller 'Eve' visiting a Middleton Railway gala in 2007

Social Events

From time to time we have social events in our Engine House, usually starting at 7.30pm and usually free. These will be advertised separately, and when they are then anyone will be welcome to attend. Refreshments will be available to buy from our shop, either during the programme or after it.

Publications

Hopefully this page has already provided plenty of reading, but there are also some publications available from our shop about our history and our locos, as well as DVDs and videos. The "Refreshments and Souvenirs" section of the Visit Us page will give you more information about these.

More Information

Other pages provide more information about:

Contacts

This page provides contact details for the railway and various bits of legal information.

Legal Information

The Middleton Railway is owned and operated by the Middleton Railway Trust Limited, which is a company limited by guarantee and registered in England, number 1165589. The company is also a charity registered in England, number 230387.

Address

The Middleton Railway Trust Ltd,

The Station,

Moor Road,

Hunslet,

Leeds,

LS10 2JQ

Contact Information

General Enquiries

E-mail:

Telephone: 07376 744 799 (please, only call between 10:00am and 4:00pm)

Membership Enquiries

E-mail:

School Visits

E-mail:

Business & Commercial Enquiries

Telephone: 0113 271 0320

Administrative Enquiries (Chairman or Secretary)

E-mail:

Website Enquiries

E-Mail:

Please note that as this charity is run entirely by a volunteer workforce, there may be times when the office is not manned and the phones not answered. Please leave a clear message, stating your name and number, preferably twice!!

We will return your call but it may take a couple of days. Thank you for your understanding.

Urgent enquiries should be sent by email to

Related Organisations

A separate page gives brief details and links to the websites of related organisations.

Privacy and Cookie Statements

Separate pages contain our statements on privacy and the use of cookies, as they apply generally to members of the public and particularly to visitors to our website.

More Information

Other pages provide more information about:

Subcategories

Projects

Projects and appeals.

Volunteering

For pages related to volunteering and membership