General

Development Projects

When the Middleton Railway Trust started in 1960 it had very little in the way of resources, and so it had to develop in order to survive. Those early development projects could only be small-scale ones - a bit of track relaid here, or a bit of maintenance work on a locomotive there - but as the railway has grown so too has the scale of the projects that it could undertake. Indeed, much of the work that constituted "a project" then would now be regarded simply as routine maintenance.

These pages therefore focus just on major development projects, with a particular emphasis on the ones that are currently taking place or have been completed recently, although eventually pages will also be created here to describe some other projects that had been completed previously.

Current Projects

Last Coals to Leeds

2018 is the 50th anniversary of the closure of the Middleton Broom Colliery, which until then had been the main focus of the existence of the Middleton Railway, since the railway had originally been built to carry coal from there into the centre of Leeds. The railway will be running a special event to mark this, and it will also be undertaking an educational project focused on primary schools in South Leeds, to raise awareness of the importance of the mining heritage of this part of the city.

Separate pages give more details of:

- the educational project; and

- the special commemorative event.

Raising Steam in No. 6

‘No. 6’ (Hawthorn Leslie Works number 3860) was built in 1935, and spent its entire working life at APCM's Cement Works in Swanscombe, Kent, along with six others. In 1971 they were replaced by diesel locomotives, and APCM donated No. 6 to the Middleton Railway. It quickly entered service, and played a major part in operating the railway's passenger trains, until it had had to be taken out of service in 1975 for an overhaul. The picture below shows it emerging from the tunnel under what was then the newly-constructed extension of the M1 motorway.

By this time there was a queue of locomotives awaiting overhaul, and No. 6's turn to enter the workshops did not come until 2001. The frames and running gear were overhauled, but then a further delay came in 2005, when the complete remodelling of the Moor Road site began, along with the construction of the Engine House building, and so work on No. 6 more or less ceased.

Meanwhile, it had become clear from an inspection of its boiler that some major repairs would be needed, and so during 2014 Gordon Newton (formerly of the boilermakers Israel Newton and Sons) visited the railway to offer advice on what work was needed, and on how much of this our members could undertake. The work that he identified has been done, and so to complete the overhaul we now have to send the boiler away to a boilermakers for the rest of the repair work. A conservative estimate is that this could cost up up to £60,000, and so we have launched an appeal for the funds needed to return No. 6 to steam by 2020, when it will be 85 years old.

Separate pages give more details of this project, and of the appeal.

Project Phoenix

During 2016 the railbus OLIVe, which is owned by our colleagues in the EM2 Locomotive Society, was the subject of an arson attack which burnt out its interior. While it was insured, the costs of actually repairing it will be significantly more than the insurance payment, and the EM2 Locomotive Society has launched an appeal for the additional funds needed to restore it to working order.

A separate page gives more details of this project and appeal.

Completed Projects

The Running Shed and "Buy a Brick" Appeal

When the railway's business plan was drawn up for the five years from 2011 to 2015, one of the proposals that had been included in it was for a project to construct a running shed, in order to improve the conditions in which operating steam locomotives were kept and prepared for service. From the outset it was clear that this project would need a significant amount of money, and so some careful financial planning would have to be the first step.

The outcome of this planning was that early in 2013 it was agreed both to set up the "Buy a Brick" scheme to raise money for this project, and to start work on planning the details of the engineering aspects of this project. The picture below illustrates the design for the bricks, and was used in the publicity material for the scheme.

Separate pages give more details of this project. It was effectively completed in December 2017, when we started to use the shed, but the formal opening ceremony for it was not until 21st July 2018.

"Brookes No. 1" Overhaul

In 2013 we were awarded a grant of £70,650 by the Heritage Lottery Fund to acquire and conserve the David Monckton collection, which consisted of the two locomotives "Brookes No.1" and "Picton" and an archive of associated documents. A major part of this work was the project concerned with overhauling "Brookes No.1", and in particular with training our younger members in the kinds of technologies that are involved in such an overhaul of a steam locomotive.

In 2013 we were awarded a grant of £70,650 by the Heritage Lottery Fund to acquire and conserve the David Monckton collection, which consisted of the two locomotives "Brookes No.1" and "Picton" and an archive of associated documents. A major part of this work was the project concerned with overhauling "Brookes No.1", and in particular with training our younger members in the kinds of technologies that are involved in such an overhaul of a steam locomotive.

This project therefore did not just restore the locomotive to the kind of condition where it both looks as well as it does in the photograph below (where it is seen approaching Park Halt with a freight train) and runs as well as it looks. The project also equipped some of our volunteers with the skills needed to achieve the same effects in the future with other locomotives, and helped us to establish the training programme that is needed to continue these developments.

Separate pages give more details of this project. It was completed in August 2017, when the locomotive returned to service.

Conserving "Picton"

The other main part of the work that is being financed by this grant from the heritage Lottery Fund is the conservation of "Picton". This had been brought back to the UK by David Monckton in 2002, and brought to the Middleton Railway, having previously spent all of its working life on a sugar plantation in Trnidad. If there are any pictures in existence of it working there, we do not know about them, but we do have the picture below, which shows its sister locomotive "Tarouba" at work on the same sugar plantation.

The other main part of the work that is being financed by this grant from the heritage Lottery Fund is the conservation of "Picton". This had been brought back to the UK by David Monckton in 2002, and brought to the Middleton Railway, having previously spent all of its working life on a sugar plantation in Trnidad. If there are any pictures in existence of it working there, we do not know about them, but we do have the picture below, which shows its sister locomotive "Tarouba" at work on the same sugar plantation.

Restoring "Picton" to working order would not be a feasible proposition, and so the main part of this project is to construct a "Picton shelter" building to protect the locomotive from the elements, once it has been treated with preservative.

Separate pages give more details of this project. The part of it that was financed by the Heritage Lottery Fund was completed at the end of September 2017, although there is still some further conservation work to do on the locomotive.

Hunslet Flatbed Wagon Restoration

As part of the preparation for our special event to commemorate the 150th anniversary of the Hunslet Engine Company, we set up a project to restore this flatbed wagon which had originally belonged to Hunslet's. The restored wagon is shown below, running in the special trains for this event with the tank from "Brookes No.1" as its load.

A separate page gives more details of this project.

More Information

Other pages provide more information about:

Building a Running Shed

What's a Running Shed?

A Running Shed is a building where we can both prepare steam and diesel locomotives for service indoors, and carry out light maintenance work on them. We will be building a shed that will be large enough to accommodate two operational locomotives. Here is an artist's impression of the planned shed, painted by Richard Stead, one of our members.

Why do we need a Running Shed?

Currently we have to prepare locomotives for service outdoors, which means they have to be stored outdoors for at least a few days before they are used. The Running Shed is being designed so that preparing locomotives, and carrying out running repairs on them, can all be done indoors. This will make the work far more comfortable, and will greatly improve the security of the locomotives.

This means that the Running Shed will better preserve our collection of locomotives, so as to allow us to keep them in the kind of condition illustrated below. As such it will help to ensure that the collection lasts for many more years into the future. The Running Shed will also give us more space in the yard and enable a better operating railway!

How will the Running Shed be built?

As the artist's impression above shows, the lower part of the walls of the running shed will be of brick construction, and the upper parts and roof will be of coated steel sheet (sometimes called "wriggly tin" by builders, although it is actually not tin at all!). The whole structure will be supported by a steel frame, which will rest on concrete foundations.

The shed can not be quite rectangular, because the site tapers (the two tracks shown in the impression merge at a turnout off to the left of the picture), and so the corner nearest the viewer has to taper off too. The shed will have smoke troughs and vents in the roof, so that the fumes produced while lighting the fires in steam locomotives can escape easily. Inside the shed there will be a pit between the rails, to make it easy to prepare locomotives, and there will also be another pit between the rails outside it (which is not shown in the impression), to simplify disposing of ash from steam locomotive fireboxes at the end of a day's operation.

These requirements mean that the process of constructing the shed will actually involve seven phases. A separate page describes how the project is structured, and the details of these phases.

When will the Running Shed be built?

Part of the answer to this is "when we have raised enough money to start", but the other part of the answer is that how long the work will take will depend on how much of it we do ourselves and how much is done by contractors. Doing the work ourselves, using our volunteer labour, is obviously cheaper than having to employ contractors, but it is also significantly slower. Some parts of the work do, however, need to be done by skilled contractors: erecting steel frames or fixing cladding sheets to them, possibly 15 feet up in the air, is not a task for amateurs! On the other hand, laying the bricks for the walls is something that we know our volunteers can do, although offers of help from experienced bricklayers would certainly be welcome!

A separate page describes the progress that we have made so far, and then other pages give more details of the work that has been done for individual phases of the project. We had hoped to see the project more-or-less finished by the end of 2016, but it actually ran on until nearly the end of 2017, and then we organised an opening ceremony in 2018.

How can you help?

There are two main ways in which you might be able to contribute to this project.

Firstly, even doing as much of the work ourselves as we can, we shall still need to raise quite a lot of money to build the Running Shed: the initial estimate was at least £46,000, and that has now gone up to about £48.000. A separate page describes the "Buy a Brick" appeal that we were running, to help raise funds to cover this cost, but this appeal has now closed.

Secondly, the parts that we can do ourselves will involve our volunteers working in all sorts of ways to contribute to the project. You can see some of these ways in the separate pages describing the work that has been done so far; there was a lot of bricklaying involved; we still have a floor to lay; we shall be installing all the electrical wiring and other fittings; and so on. If you have almost any kind of practical skill we will probably be able to use your help in this project. Please see our separate membership page for more details of how to get involved.

Go on to the next stage in this project.

More Information

Pages about other projects:

- Last Coals to Leeds;

- Raising Steam in No. 6;

- Project Phoenix;

- Overhauling "Brookes No. 1";

- Conserving "Picton".

Other pages provide more information about:

Opportunities for Volunteering

The railway has many different areas of activity, and there are opportunities to volunteer in all of them. The rest of this page describes some of the main options, but there are plenty of others.

The Locomotive Footplate

A driver and fireman on the platform.

Every young child's dream - becoming an engine driver!

Since we are a heritage railway, there are opportunities to experience working on a variety of steam and diesel locomotives.

Starting as a Shunter, then for a steam locomotive you can work your way through the ranks to Cleaner, Passed Cleaner, Fireman and then to Driver. The equivalent for a Diesel Locomotive is again to start as a Shunter, and then progress to Second Man and to Driver.

Engineering

An engineer in the workshop, painting part of a locomotive.

Maintaining and Restoring our historic rolling stock

Gain new skills and help to safeguard our engineering heritage by helping to maintain and restore our historic fleet of steam and diesel locomotives.

There are great opportunities to volunteer alongside experienced engineers and craftsmen, working behind the scenes to preserve the past and secure the future of the Middleton Railway. You would be helping to keep alive the skills that were developed in Leeds to enable many of these locomotives to be constructed.

Shop Staff

Shop staff behind the counter.

The public face of the railway

Volunteering in the Middleton Railway's Gift Shop provides a great opportunity to interact with visitors and passengers. The social hub of the railway, the gift shop offers an essential support service covering all aspects of the railway, from operations to timetables.

Work alongside friendly, polite and approachable volunteers and enjoy a direct relationship with our passengers. Roles include: Ticket Sales, Customer Support, Shop Assistant and Refreshments.

Guarding

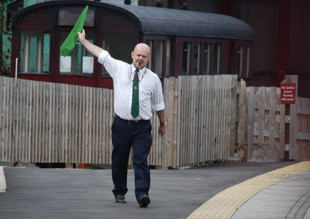

A guard giving the signal for a train to depart.

Keeping passengers safe on the trains

Train Guards interact directly with the passengers, taking on the responsibility of passenger safety and ticket collection. Personable and smartly dressed, the Train Guards are a key part of the public face of the Middleton Railway.

Permanent Way Department

A gang working on the track.

Keeping the railway line in good order

The Permanent Way Department ensures that the track and associated infrastructure are well maintained for our passenger's safety and enjoyment.

The department is responsible for all maintenance and inspection of the track, the ground over which it runs and the surrounding hedges and fences. As such it is a vital part of the railway, and consists of a wide variety of volunteer staff roles and skills.

Other Opportunities

A member of our education team in action.

There really is scope for everyone to contribute

There are many other opportunities for volunteering, besides the ones described above. From building maintenance to running events, from gardening to marketing, if you have some special skill we can find a way of using it.

In particular, there are opportunities in our education team; as part of our museum staff (where we are hoping to establish a team of "explainers" who can help people understand the exhibits in our display hall); and in helping with the organisation of our Santa Specials and other events.

For more details of some of these opportunities, you can download a copy of our leaflet about volunteering.

More Information

If you want to know more about getting involved, other pages of our web site will provide more information about:

Also, for other topics other pages of our web site will provide more information about:

Running Shed - The Project

A building such as this running shed is a bit like a tree, in that there is almost as much below ground that you don't see as there is visible above ground. Furthermore, all of the construction work below ground has to be done before anything visible can be erected. Not only that, but also all of the planning work has to be done before any construction at all can begin.

Project Structure

For these reasons, the overall project to build the running shed (as opposed to just raising funds for it through our "buy a brick" appeal) actually consisted of 7 phases. Some of these phases then involved several stages, and in turn some of these involved several steps, which are all described below.

1. Overall design and planning

The initial stage in this phase was to get from a rather vague "it would benefit the railway if we had a running shed" to a fairly precise "this is what we want to build, and where". As such this stage involved a lot of discussion of what we wanted and why, and making careful estimates of how much such a building might cost.

Once these had been decided, the main work in this phase was to design the building in enough detail that we could then apply to the City Council for planning permission for its construction. As part of this the costs needed to be estimated more carefully, as there would be no point in obtaining planning permission for it unless we were confident that we would then be able to afford to build it.

Making such an application actually has two stages to it. The first is what used to be called applying for outline planning permission, but is now known as a "pre-application". This stage is intended to check that a project is in principle worth submitting for full planning permission. Fortunately our pre-application did not identify any problems with the proposed building, and so very little additional design work was needed in order to progress to an application for full planning permission.

2. Construct a pit

One of the decisions made during phase 1 was that the running shed needed to have a pit between the rails. This was because preparing a locomotive for service involves the crews going underneath it, in order to check the moving parts that are between the frames of the locomotive, and also to oil up these parts. This is all much easier to do if there is a pit to work from.

Constructing this pit involved extending the existing outdoor pit, and so this had to be done before any other construction work. It also had to be completed before the detailed design work on the building could start, just in case the excavations for the pit uncovered any problems with the ground that might affect the design.

3. Detailed design and tendering

As illustrated in the page for the overall project, the building was constructed round a steel framework, with a brick dado wall for the lower parts of the walls, and with the upper parts of them and the roof being clad with coated steel sheet. For such a building a specialist firm can design and fabricate the steel framing and the cladding far more efficiently than our volunteers could. Hence, this phase of the project actually had three stages.

The first stage was that we had to prepare yet more drawings, and discuss these with the City Council to ensure that there would be no problems with obtaining Building Regulations approval when that stage was reached.

The second stage was then to put the detailed design work out to tender, based on these drawings, and then consider the tenders that were submitted by the various interested contractors for completing the design work and doing the key parts of the construction. This stage ended with a tender being accepted and a contractor appointed.

The third stage was then that the contractor had to carry out the specialised calculations that are needed to ensure that the foundations and frame of the building are strong enough (for instance, to resist loads from wind blowing on the sides or ends, or snow building up on the roof), and to complete the detailed design. They then obtained the formal Building Regulations approval from Leeds City Council, so as to ensure that when constructed the building is safe to use.

4. Construct foundations

As soon as the design of the building had been completed, and Building Regulations approval obtained, work could start on the next phase, which was the construction of the foundations. We had originally expected to do much of this work ourselves, but during the tendering process in phase 3 it became apparent that in principle it would be better if the contractors were to construct the foundations, so as to ensure that these would exactly match the frame.

As part of accepting the tenders, therefore, it was decided that the contractors should also construct the foundations. An important feature of these is that they are not just a mass of concrete, but also include steel reinforcement that must be secured together, and this all needs to be designed to provide adequate strength.

A separate stage within this phase was that an oil separator needed to be installed, to remove any oil from water draining out of the shed, and this required a hole roughly 2.8 metres (9 feet) deep. This was sufficiently deep that we certainly could not carry out this bit of the work safely with the equipment that we have. Initially it was not clear whether this would have to be done as part of constructing the foundations, but it was established that it could be designed in such a way that it did not. Consequently, separate tenders were invited from specialised contractors for doing this excavation and installing the oil separator.

5. Erect framework

As soon as the foundations were complete, then the pre-fabricated steel frame for the building could be erected on them. This was also done by the main contractor, who both supplied and erected the frame. This phase was extremely important, since all the rest of the building is supported by the frame, and it had to be constructed so that it matches exactly the foundations and the cladding sheets. Despite this, though, this phase was the shortest, and it took less than a week.

6. Roofing, cladding and brickwork

Once the steel frame was in place, then the original plan had been that work could start on fitting the cladding sheets for the walls and roof. This too was done by the main contractor, since they were also supplying the cladding sheets. In practice, though, the advice from the contractors was that once the cladding sheets for the roof had been fitted, then it would be better to lay the bricks next, and finally fit the cladding sheets for the walls to match the brickwork.

So, once they had constructed the roof, then we started laying the bricks - and there were about 9,000 of them! So, the rest of this phase was actually the part of the project that involved the most work, by quite a long way. Just how quickly we were able to progress this was one of the main things that determined when the project would be finished.

7. Fitting out

Once the walls and roof were in place, then the next step was to fit the doors, which gave us a secure building.

At this point we were able to start installing the electrical wiring needed for lighting, power supplies and ventilation. Also we were able to start installing the internal smoke troughs in the roof, which will catch and extract the smoke when eventually locomotives are being lit up in the building.

Project Timing

From previous construction projects we knew that there were all kinds of external factors which would affect how quickly we could carry out the work. A separate page describes the progress with the project, and the various delays that we encountered. We would have liked to hope that there would not be too many of these, but from previous experience we doubted that everything would really run as smoothly as that.

Thus, while we had started out hoping that it would all be finished by the end of 2016, the experience of having constructed our workshop buildings meant that we were not surprised when it actually took until almost the end of 2017 to finish it.

The keys to the good progress that we did make with this were fundraising and volunteer manpower - and that applies just as much to our other current projects, too. Please consider helping by volunteering at the railway. As the description of the work done so far makes clear, while contributing to such projects may be hard work it is also rewarding work - much more satisfying than just going to a gym for some exercise!

Go on to the next stage in this project.

Go back to the previous stage in this project.

Return to the overall description of this project.

More Information

Other pages about this project and the "Buy a Brick" appeal:

- An overview of the project and the appeal;

- The "Buy a Brick" appeal;

- The progress with the project;

- The construction of the pit;

- Design and site preparation;

- Construction of the foundations;

- Erection of the framework;

- Construction of the walls;

- Fitting out;

- The opening ceremony.

Other pages provide more information about:

Running Shed - Progress

A separate page describes the overall structure of the project to build the running shed, and in particular describes the 7 phases through which the project proceeded. This page describes how the project actually progressed, in terms of which of these phases were completed when.

1. Overall design and planning

This phase involved designing the building in enough detail that we could then apply to the City Council for planning permission for its construction. The phase started in May 2013, when we initially took the decision to go ahead with the project, on the basis of estimates that the building was likely to cost about £46,000.

This phase took much longer than we would have liked, largely because of delays in the process of obtaining planning permission. The material for the "pre-application" stage of this process, which is intended to check that a project is in principle worth submitting for full planning permission, went in to the City Council during September 2013, which unfortunately was just after all the plans for the Leeds Trolleybus system had been submitted. This meant that our project had to wait until the planners had got their heads round that lot, and so it actually took almost 10 months to be processed, whereas these pre-applications are normally supposed to be processed in about 6 weeks at most.

Once the pre-application stage had finally been completed, and we had what used to be called outline planning permission, there was very little more work that had to be done to produce the application for full planning permission. We were therefore able to submit this in August 2014, and the processing of it ran to something much closer to the expected schedule. Full planning permission was therefore received in December 2014.

2. Construct a pit

One of the decisions made during phase 1 was that the running shed needed to have a pit between the rails, which would be constructed by extending the existing outdoor pit, so that this had to be done before any other construction work. Apart from a few minor bits of work, however, we could not start this until we had received planning permission, and then for obvious safety reasons we could not go digging holes next to track on which trains were running. Consequently, the construction of this pit extension could not start until January 2015, after our Santa Special trains had finished running in December 2014.

A separate page describes in detail the work that was done for this phase, which was finally finished in early April 2015, by which time the project had cost just under £7,900.

3. Detailed design and tendering

The building is illustrated in the main project page, and for this kind of construction a specialist firm can do a far more efficient job of designing, fabricating and then assembling the steel framing and the cladding than our volunteers could. Hence, after the preparation of yet more drawings, and discussions with the City Council to ensure that there would be no problems with obtaining Building Regulations approval when that stage was reached, this detailed design work was put out to tender in November 2015.

After discussions with the interested contractors the tenders were submitted, and they were considered in January 2016, when the one from Midbrook Steel was accepted. By this time the estimated cost to complete the project had risen to just under £49,000 (as compared with the original estimate of about £46,000), and of course this is on top of what had been spent in phases 1 and 2.

In late February 2016 a contract was signed with Midbrook Steel for the construction of the foundations, the steel frame and the steel cladding. As part of this they would carry out the specialised calculations that are needed to ensure that the foundations and frame of the building will be strong enough to produce a building that will then be safe to use.

Alongside this design work, the final preparation of the running shed site needed to be done, to clear it ready for construction work in the next phase to start. Also, it had been established during the discussions with the contractors that part of the fence to the whole site would need to be removed, to allow access to the western wall of the shed. This would require a temporary closure of the footpath that runs along this side of the site, and this too has to be approved by Leeds City Council.

Eventually formal Building Regulations approval was given, as was the approval to close the footpath, and once the last bits of site preparation had been completed construction work could be scheduled to start, which tentatively was set for the end of May 2016.

4. Design and construct foundations

Having completed the design of the building, obtained both Building Regulations approval and approval to close the footpath, and prepared the site, work could start on the next phase, which is the construction of the foundations. As explained in the page describing the project structure, we had originally expected to do much of this work ourselves, and had intended to try to schedule it for the period from January to March 2016 - because again, as with the pit, it would not be safe to be digging holes next to track on which trains are running.

This plan had, however, changed during the tendering process in phase 3, since it became apparent that it would be better if the contractors were also to construct the foundations, even though this would be more expensive, because this would ensure that the foundations and the frame will match each other exactly. As part of accepting the tenders, therefore, it was decided that Midbrook Steel will also be constructing the foundations, which they could do quickly enough that it would not cause any disruption to the operation of trains.

As described above, with work on the detailed design of the frame and the foundations well under way, as was site preparation, it was hoped that the construction of the foundations could start in mid-April 2016. Unfortunately, though, the formalities involved in arranging for the temporary closure of the footpath alongside the site delayed things a bit further, and so this date slipped back, at least into May.

As well as the foundations, an oil separator needed to be installed, and (again as explained in the page describing the project structure) this would require a hole that would be sufficiently deep that we could not carry out this part of the work safely ourselves. Therefore, separate tenders were invited from specialised contractors to do this bit of the excavation and installation for us. These were received in mid-April, and Drainstore were appointed to do this work.

Finally, on Tuesday 31st May the contractors arrived to start work on the construction of the foundations. As promised they made very rapid progress, and in barely a week the foundations were complete. The work of installing the oil separator then had to be scheduled so that it would not affect our train operations, which was tricky since we had three special events between the middle of June and the middle of July: the Model Railway Exhibition, the Steampunk event and the Victorian Gala. Eventually the work was carried out during the week before the Victorian Gala (ie the week beginning Monday 11th July), and completed in good time to avoid any disruption to the gala.

5. Erect framework

As soon as the foundations had been completed and the oil separator installed, then work started on erecting the pre-fabricated steel frame for the building. This too was done by Midbrook Steel, who both supplied and erected the frame. While this phase is extremely important, because all the rest of the building is supported by the frame, it was only expected to last for a week at most, and that is just what happened. It followed on immediately from phase 4, with just the railway's Victorian Gala weekend (16th and 17th June 2016) in between, and was indeed completed within the week. It was then expected that it would run straight on into phase 6, but the contractors recommended that this plan should be changed, partly so as to fit in with the construction of the Picton shelter building.

6. Roofing, cladding and brickwork

Once the steel frame was in place, then Midbrook Steel, who were also supplying the cladding sheets, could have started work on fitting them to the frame to form the walls and roof. They fitted the roof, effectively as part of phase 5, but their recommendation was that it would be better if the brickwork of the walls were to be constructed next, before the cladding sheets were fitted above it.

Thus, the next bit of this stage was that we prepared to start laying the bricks. This sounds easy if you say it quickly, but there were at least 9,000 of them! So, we knew from experience that actually the rest of this phase would involve more work on our part than any of the rest of the project - even the construction of the pit. We tried hard to progress it as quickly as we could, but it actually ran on into early December 2016.

Once the bricks had been laid, then Midbrook returned to site, just after Christmas, and fitted the cladding sheets for the walls.

7. Fitting out

By early January 2017 the walls, doors and roof were complete enough for the building to be more-or-less secure, once the main doors had been fitted. Discussions had been going on as to whether this should be a roller shutter door or a pair of swing doors, and eventually it was decided that swing doors would be better, because a roller shutter door would have to be mounted inside the building, and so would reduce its effective length by over a foot - and this extra bit of space would make it much easier to work in the building.

So the doors were constructed, and as soon as they were fitted and the building was secure then we were able to start installing internal features. These included flooring, the electrical wiring needed for lighting, power supplies and ventilation, and also the internal smoke troughs in the roof, which will be part of the ventilation system.

We had rather hoped that a lot of this would be finished before we started running trains again in March 2017, but then we had hoped that it might be finished by the end of 2016, and from our experience of having constructed our other workshop buildings we were well aware that all sorts of delays could occur. Consequently, we were not surprised that this was not achieved, and actually the last bits of the work ended up running on almost to the end of 2017.

Go on to the next stage in this project.

Go back to the previous stage in this project.

Return to the overall description of this project.

More Information

Other pages about this project and the "Buy a Brick" appeal:

- An overview of the project and the appeal;

- The "Buy a Brick" appeal;

- The structure of the project;

- The construction of the pit;

- Design and site preparation;

- Construction of the foundations;

- Erection of the framework;

- Construction of the walls;

- Fitting out;

- The opening ceremony.

Other pages provide more information about:

Subcategories

Projects

Projects and appeals.

Volunteering

For pages related to volunteering and membership