General

S8: Peckett 2003

0-4-0ST steam locomotive "John Blenkinsop"

| Built | 1941, at Bristol (class W7) |

| Weight | 30 tons 0 cwt |

| Length over buffers | 23' 2" (approx 7.0 m) |

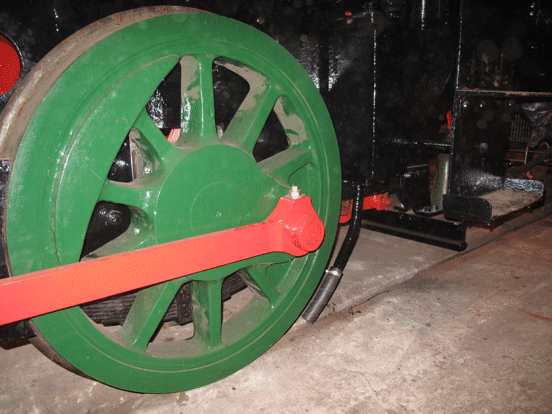

| Driving wheels | 3' 3" diameter (approx 98 cm) |

| Cylinders | 2 (outside), 14" diameter (approx 355 mm) |

| Previously worked | British Nuclear Fuels, at Salwick, near Preston |

| Entered collection | Purchased from British Nuclear Fuels in 1972 |

| Current status | On loan to the Ribble Steam Railway at Preston |

More details of this locomotive are given in our stockbook.

Go on to steam locomotive S9: Manning Wardle 1601.

Go back to steam locomotive S7: Hartmann 2110.

Return to the list of steam locomotives.

More Information

Other pages provide more information about:

Museum

We have a fascinating collection of objects which between them illustrate the history of the Middleton Railway, the history of industrial railways like it, and the history of the industry that grew up in the Leeds area for building railway locomotives, cranes and other associated machinery. These pages will tell you more about these objects.

Rolling Stock Collection

Our collection of railway rolling stock (ie locomotives, coaches, wagons, etc) is the heart of our museum collection. Separate pages give more details of different groups of rolling stock, as follows.

- Steam Locomotives;

- Diesel and Electric Locomotives;

- Coaches (and other passenger vehicles);

- Goods wagons;

- Cranes;

- Made in Leeds

Some of these items of rolling stock are operational, meaning that you may be able to see them running in trains (or even ride in them or behind them), while others are in the course of being restored to operational condition in our workshops, so that normally you would not be able to see them. Many of the rest are on display while they are waiting for work that will restore them to operational condition; and there are just a few that are simply waiting for this sort of work, but are not yet in a condition to be displayed properly.

Other Items

Details of other items in our museum collection will be added to these pages in due course.

History

A separate page summarises the history of the Middleton Railway, as follows.

A much more detailed account of this history is published in our official history, which is available from our shop.

For our Diamond Jubilee in 2020, the corona virus pandemic meant that most of the activities to mark this anniversary had to be cancelled, and so instead we created a separate page containing archive Images.

More recently, following the death of HM Queen Elizabeth II, we created a page containing a reflection on the passage of time, which is what history is all about.

More Information

Other pages provide more information about:

"Brookes No. 1" Overhaul Phase 3

The page describing phase 2 of this project explains that phases 2 and 3 of it overlapped a bit, in that phase 2 was concerned with overhauling the frames and the running gear, and so effectively finished once the frames were back on the wheels. Then, phase 3 covers the rest of the re-assembly of the locomotive, but one of the first stages in this was re-tubing the boiler, and this actually started early in July, while the last bits of work on the running gear were being completed.

The page describing phase 2 of this project explains that phases 2 and 3 of it overlapped a bit, in that phase 2 was concerned with overhauling the frames and the running gear, and so effectively finished once the frames were back on the wheels. Then, phase 3 covers the rest of the re-assembly of the locomotive, but one of the first stages in this was re-tubing the boiler, and this actually started early in July, while the last bits of work on the running gear were being completed.

This page therefore describes phase 3, while the previous page describes the last bits of work in phase 2. Click on the links below to track our continued progress:

- July 2016

- August 2016

- September 2016

- October 2016

- November 2016

- December 2016

- January 2017

- February 2017

- March 2017

- April 2017

- May 2017

- June 2017

- July & August 2017

July 2016

The first step in re-tubing a boiler is to fit all of the tubes into it, by pushing them through from the front, while somebody in the firebox uses a short bar to catch the rear end of each tube and guide it into its correct hole. They then use a depth gauge to ensure that each tube sticks out into the firebox by the same amount.

Before each tube is inserted, however, its ends need to be polished with a strip of emery cloth, so as to remove any rust or other dirt which would prevent it from fitting tightly into the tubeplate when it is expanded. The picture below shows two of our volunteers polishing the front end of one of the tubes in this way, before they push it fully into place in the boiler.

Once all of the tubes have been fitted into their holes, then the process of expanding each tube to fit tightly in the tubeplates can begin. This is done using a tool called a tube expander, which consists of a metal cage that contains a number of rollers arranged round a central shaft and almost parallel to it. The central shaft tapers, and the rollers are mounted into the cage so that they are at a slight angle to the central shaft. Consequently, when the central shaft is turned the rollers gradually pull themselves into the end of the tube, and expand it to become a tight fit. In the picture below one of our volunteers is working in the firebox to expand a tube: usually he would use a ratchet to turn the expander, but since this tube is in the top row it is sufficiently close to the roof of the firebox that there is not room for the ratchet, and so he is having to use a spanner instead.

While this is being done, the other end of the tube has to be held tightly, to stop the tube turning in the tubeplates, but once the first end has started to grip then a second tube expander can be used at the other end, so as to expand both ends at once. Once one tube has been expanded it is marked, to show that is has been done, and work starts on the next one. The picture below shows the volunteer at the smokebox end taking it easy for a minute or two, once all the tubes in the central left column have been expanded, and work has started on the central right column, as shown by the paint marks above the tubes that have been completed.

In the picture above it will be noticed that there are a number of holes that have not got tubes in them: four across the top, above the tubes, and then three at the bottom, although only two of these are visible. These holes are for the washout plugs, which are screwed into them, but about once a year they need to be taken out to allow the inside of the boiler to be washed out, to get rid of the sludge and scale that accumulates.

Steady work meant that by the end of July all of the tubes had been expanded, and the picture below shows the two happy volunteers celebrating this milestone. Of course, at this stage no water had been put in the boiler, and experience says that once this is done some more expanding will almost certainly be needed.

August 2016

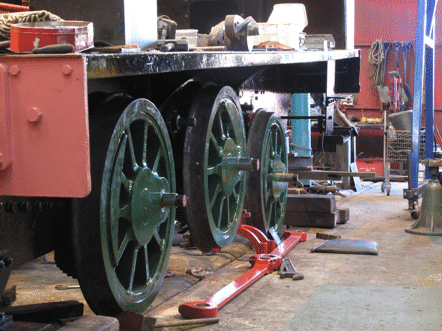

Meanwhile, back in the workshops the side rods were being refitted, only to discover that the rear left-hand axlebox had not been fitted correctly, despite all the care that had been taken over the measurements. The error was only a matter of 20 thousandths of an inch (half a millimeter in metric units), but it was enough that as a result the left-hand side rod would not fit.

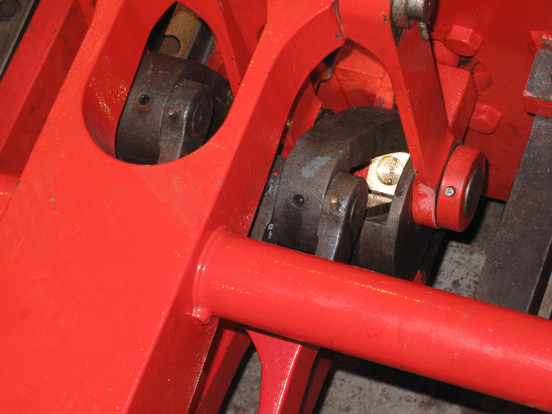

The rear end of the frames therefore had to be jacked up again, as shown in the picture below, so that this axlebox could be dropped out and the shims adjusted to that it would fit correctly. The side rod is lying on the ground, ready to be tried again once the axlebox has been refitted. Also on the ground can be seen two of the eccentric straps, which had not yet been fitted onto their eccentric.

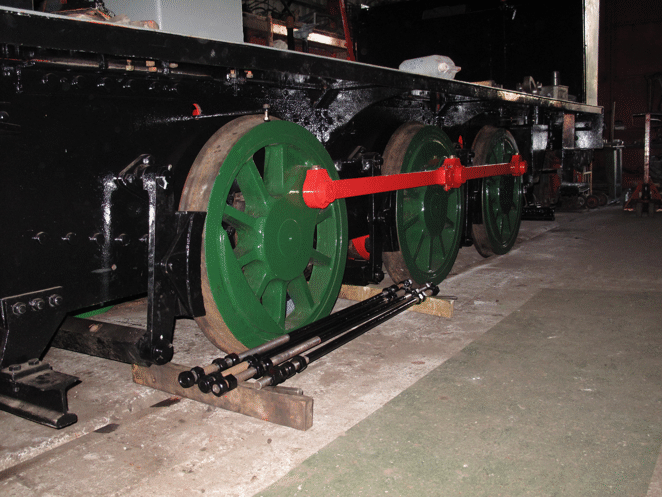

Once the shims in the axleboxes had been adjusted, it was refitted and the frames lowered down again, and then the side rods could be fitted, as shown in the picture below.

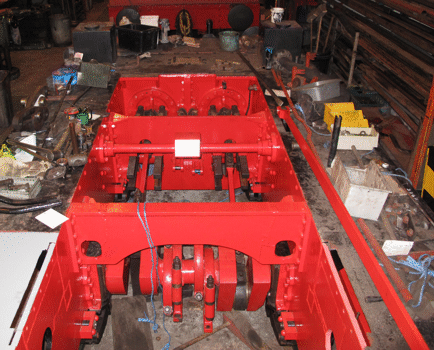

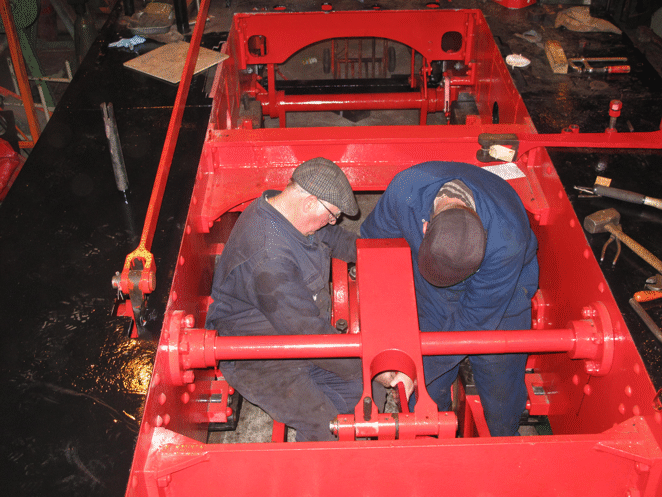

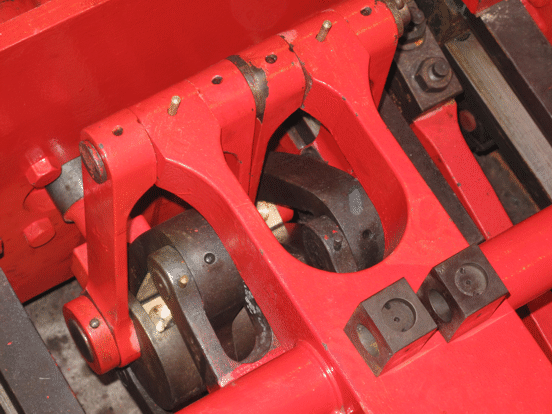

With the side rods fitted, the next step was to fit the connecting rods, which link the crossheads to the driving axle, and so transmit all the power from the pistons to the wheels. The picture below, which was taken from the cab footplate, shows the two connecting rods in place. The next step in assembling the motion will be to fit the four eccentric rods, which connect the eccentric straps (that can be seen in the picture, already fitted round the eccentrics) to the two links which are the main part of the valve gear.

This picture also shows very clearly the construction of the frames, with the two main frame plates (one on each side) running the length of the locomotive, and the various cross-pieces (known as the frame stretchers) rivetted to them. We were fortunate in that there were no bends in the frame plates or stretchers that needed to be repaired (unlike one or two of the locomotive overhauls that we have done).

September 2016

Meanwhile, when the blast pipe had been taken off the locomotive while it was being dismantled, it had been obvious that it was not in a fit condition to be put back. The picture below was taken when it was on its way to the scrap pile, and shows clearly the patch near the bottom that would turn into a hole if any attempt was made to re-use it.

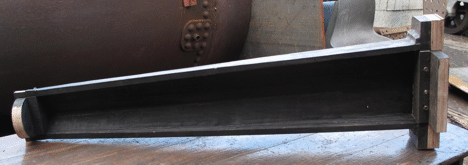

Therefore, a new blast pipe had to be made. This involved manufacturing a wooden pattern, which is shown in the picture below, and this was then taken to a foundry who made the necessary sand moulds from it, and then cast a new blast pipe in these moulds. For this purpose the outside of the pattern was used to make two half-moulds for the outside of the new blast pipe, and similarly the inside of the pattern was used to make two half-moulds for the sand core, which forms the hole up the middle of the blast pipe.

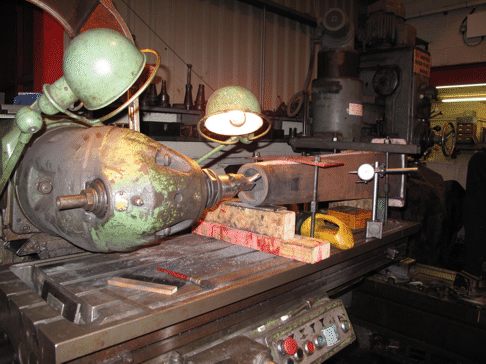

This new blast pipe then needed to be machined to fit onto the locomotive, by firstly machining flat the bottom flange and then drilling the holes in it for bolting it into place on top of the cylinder block. Then, secondly, the hole up the middle of the blast pipe, which directs the exhaust steam from the cylinders up the chimney, needed to be bored out to size. The picture below shows this being done on the milling machine.

October 2016

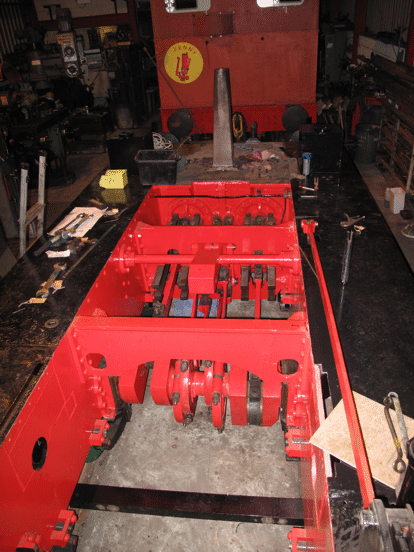

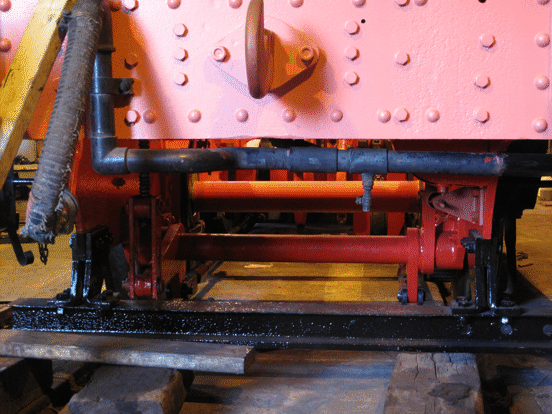

On the chassis of the locomotive the next step was to fit the brake gear. The picture shows the brake hangers and brake blocks fitted for all of the wheels, and the cross-beams which connect the pairs of brakes on each side of the locomotive. The pull-rods which apply the brakes connect these cross beams together, but in this picture they are still on the ground alongside the wheels, waiting to be fitted.

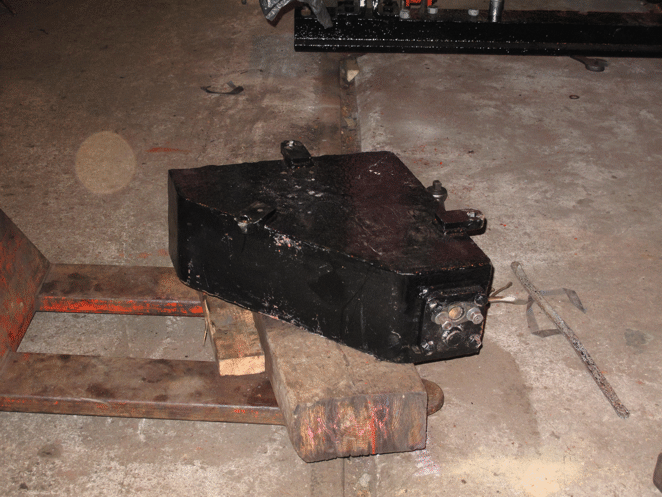

As well as the brake gear, the sanding gear needed to be fitted too. This allows the driver to drop sand under the wheels to give a better grip on the rails in wet or icy conditions. It consists of four sandboxes, two mounted in front of the front wheelset and two mounted behind the rear wheelset. Each sandbox then has a valve inside it to control the flow of sand out through a pipe attached to the bottom of the box, and these valves are connected by operating linkages to a lever in the cab.

The picture below shows one of the sandboxes after it had been cleaned up and painted, waiting to be mounted onto the locomotive frames. The bottom of the box is nearest the camera, and the mounting for the sand pipe can be seen clearly: the pipe itself will be fitted after the box is in place on the frames.

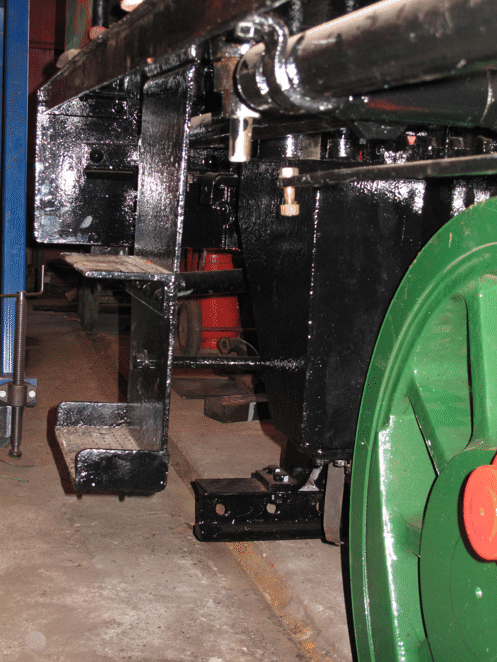

The next picture then shows the rear sandbox for the right-hand side of the locomotive in place on the frames, behind the cab steps, and waiting for the operating linkages and the sand pipe to be fitted. The large pipe that is visible above the sandbox is for the vacuum brakes.

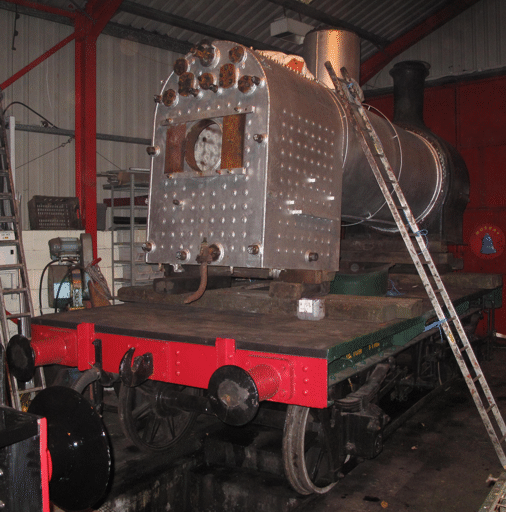

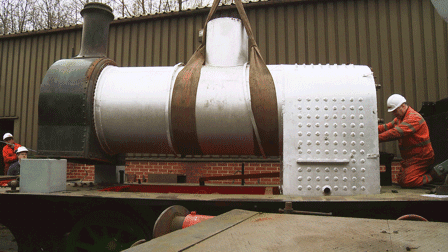

Meanwhile, the boiler had been brought into the workshop,to allow fittings to be attached to it, to prepare it for hydraulic testing. It is shown in the picture below, and is carried (very appropriately) on the restored flat-bed wagon that had originally been used at the Hunslet Engine Company's works for just this kind of job. It can be seen that the boiler drain valve has been fitted to the rear of the firebox, and also the top plate for the dome has been fitted.

As well as preparing the boiler for hydraulic testing, work is continuing on the frames, and the picture below (taken from on top of the frames at the front of the locomotive) shows the eccentric rods being fitted. These are key components of the valve gear, which controls the admission of steam to the cylinders and the release of exhaust steam up the chimney.

As will be obvious, there is not a lot of room between the frames for carrying out this kind of work!

November 2016

By early November fitting of the valve gear had been completed, apart from two small components, known as the die blocks, which were currently in place but needed replacing. The picture below (taken from the cab floor of the locomotive) shows all of the valve gear connected up, although the die blocks are not visible in this picture.

Below the frames, behind the rear stretcher, can be seen the rear brake cross-beam, which is still waiting for the pull-rods to be fitted. They would have been in the way of the work if they had been fitted before the valve gear was complete.

At the front end of the locomotive it can be seen that the new blast pipe has been mounted temporarily on the top of the cylinder block, to make sure that it fits correctly. It will be taken off again before the boiler is lifted back into the frames, so that it will not be in the way of this operation.

Meanwhile, the last bits of the brake gear had been fitted, including the cross-shaft which operates it all. This is shown in the picture below, which was taken from the back of the locomotive. The shaft is painted red, and the horizontal lever at the left-hand end of it is operated by the handbrake, while the vertical one at the right-hand end is operated by the steam brake cylinder. The two levers below the cross-shaft are connected to the brake pull-rods (actually painted black, although the left-hand one is reflecting the red of the frames). These run forward to the rear brake cross-beam (also painted black, although part of it is hidden by the cranks on the axle), which connects together the two brake levers and their brake blocks that are in front of the rear axle.

The big black cross-beam below all of this brake linkage is known as the derailing beam, and is firmly bolted to the frames. It is there so that if any of the wheels did come off the track (which was not an uncommon occurrence on some industrial railway systems) the locomotive would not drop down too far below the level of the rails, and so would not damage the brake gear.

December 2016

A lot of the work during December 2016 was focused on the details of preparing the boiler for hydraulic testing, but this is one of those frustrating jobs where the progress that is being made is hardly visible. One job that is visible, however, is that two new die blocks were made and fitted. The picture below shows the two old blocks sitting on top of the lifting arm for the links, with the new blocks partly visible in the links below them.

The next picture then shows a closer view of one of the new die blocks, in the right-hand link.

January 2017

As with the previous month, a lot of the work during January 2017 was focused on continuing with the preparation of the boiler for hydraulic testing. Alongside this, though, a lot of checking had to be done of the work on the chassis, to ensure that everything had been properly finished off. One obvious bit of this work was the fitting of the sand pipes, and the picture below shows two of our volunteers carefully adjusting one of the front sand pipes to make sure that it will drop the sand on the rail, rather than either side of it.

The rear sand pipes have already been fitted, and the picture below shows the left-hand one of these complete and properly adjusted.

February 2017

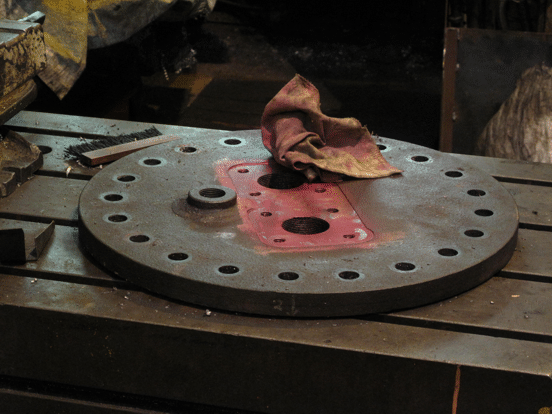

During the preparation of the boiler for hydraulic testing, a potential problem had been identified with the way in which the safety valves were mounted on the dome cover, and discussions with the boiler inspector during January had resulted in the decision that they would need to be improved. This would require the original mountings to be machined off the top of the cover, so as to produce a flat surface onto which separate mountings could be bolted. The picture below shows the dome cover after this machining had been done, and after the machined section had been coated with a red-coloured penetrating dye to check that the machining had not produced any cracks in the cover.

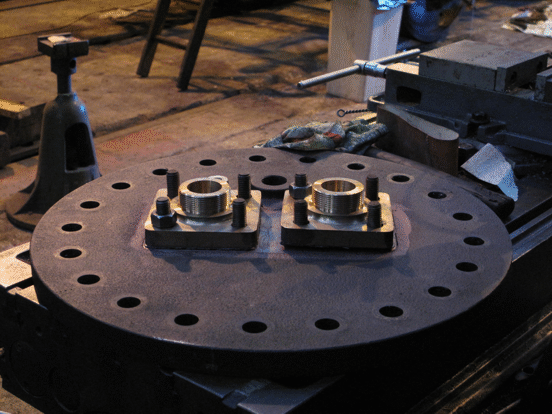

The separate mounts for the safety valves were then cast in brass and machined up, and the picture below shows them being bolted onto the dome cover.

Once these mounts had been fitted, then the dome cover was bolted into place, and everything made ready for the official hydraulic boiler test, to be conducted in the presence of the boiler inspector. This involved waiting for weather that was warm enough to conduct the test - not simply above freezing (because filling the boiler with water if there was a risk of freezing temperatures would be very likely to do it serious damage), but above 10 degrees C.

March 2017

Fortunately we did not have to wait too long, and a few warmish days at the beginning of March enabled us to run the hydraulic test, which was passed without a problem. Not only that, but we were advised by the boiler inspector that he would be happy to have the official steam test done with the boiler back in the chassis, rather than having to wait until the steam test had been done before replacing the boiler in the frames.

The first stage in replacing the boiler in the chassis was to lift it off the wagon, and then lower the firebox onto the new ashpan, so that this could be fitted to the bottom of it. The picture below, taken from the cab footplate on the chassis, shows the ashpan being fitted.

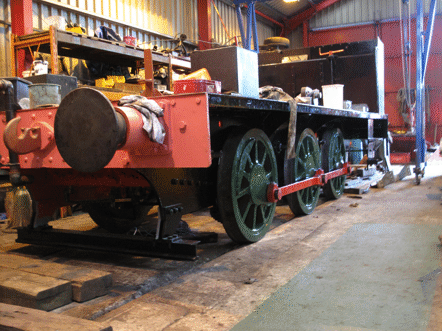

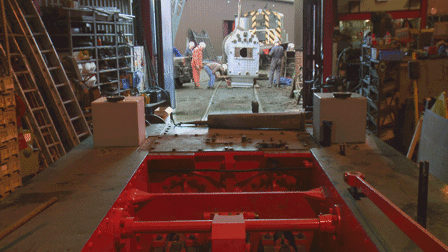

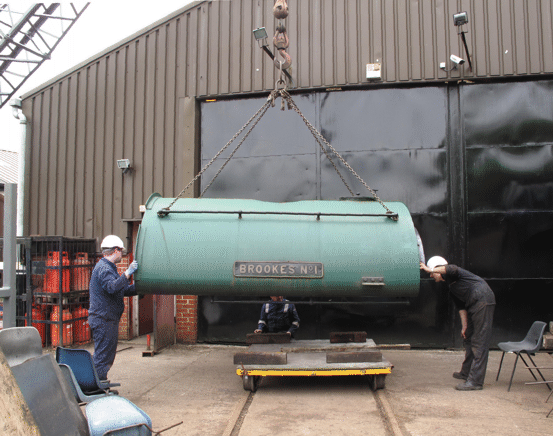

Once the ashpan had been fitted, then the whole boiler was lifted and the chassis was pulled out of the workshop, as in the picture below, and into position ready for the boiler to be lowered onto it.

With the chassis in the right position, the boiler was swung round on the crane and positioned over the chassis ready for lowering to start, as in the picture below.

The tricky bit of the lowering was to ensure that the firebox and ashpan were fitting nicely between the frames, as they are in the picture below. Once this had been achieved then the last bit of the operation was simply to lower the boiler the rest of the way until the smokebox and the firebox mounting brackets were sitting in position on top of the frames.

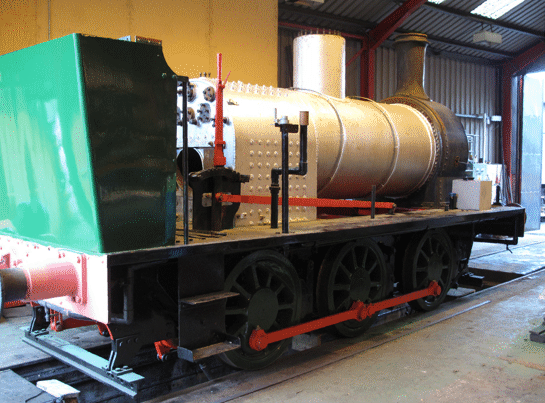

With the boiler in place, the locomotive was moved back into the workshop, so that it could be prepared for steam testing.

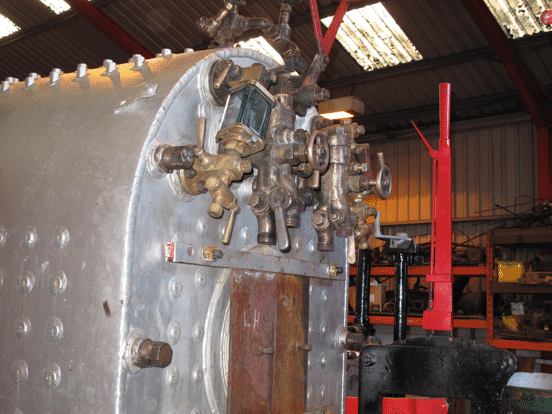

This involved attaching the various boiler fittings, and the picture below shows the boiler backhead with the water gauges and the injectors all in place. Also the steam manifold is just visible on top of the firebox.

Meanwhile, outside the workshop preparatory work on the boiler cladding sheets and the cab had begun, and the picture below shows one of the cladding sheets being sanded down, in front of the boiler of No. 6.

The cab also needed similar treatment, as in the picture below. The object next to it, under the silvery coloured cover, is the new boiler that had been built for the Sentinel. This boiler had been delivered a few days earlier, and was stored here temporarily until it could be lifted into place - but that's a separate project!

April 2017

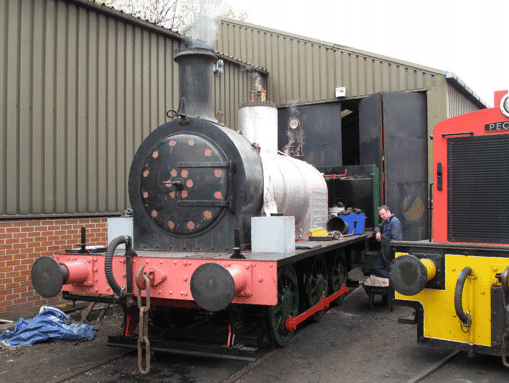

As soon as all the fittings had been attached to the boiler, it was possible to steam test it. The locomotive was pulled outside the workshop, the boiler filled with water, and a fire lit. By about lunchtime, when the picture below was taken, we were well on the way to having full steam pressure. Once that was reached, and there were no signs of any leaks or other problems, the boiler inspector (seen in the picture watching carefully for any signs of problems) was able to declare that the boiler was fit for use. Phew!!

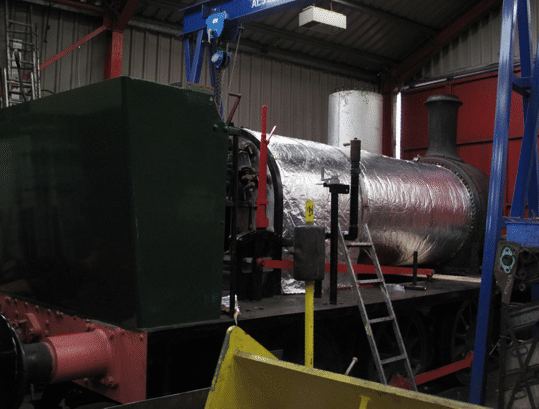

As soon as the boiler had cooled down the locomotive could be pushed back into the workshop, and then the boiler lagging could be fitted. This is rockwool insulation backed with aluminium foil, and the picture below shows the lagging in place.

May 2017

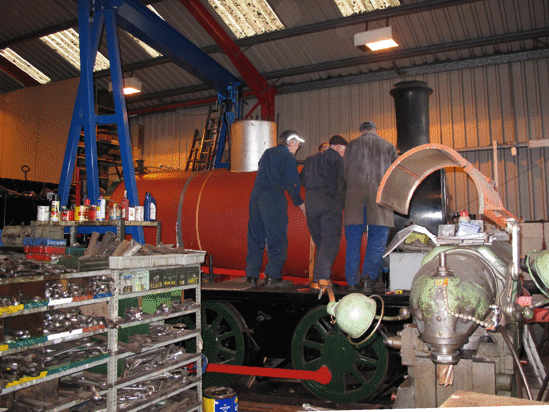

With the lagging in place the next step was to fix the cladding sheets, which will hold it in place. By this time these had been painted in red oxide primer, and the picture below shows them being fitted round the boiler. They were held in place temporarily with the orange webbing straps that can be seen, and then the steel boiler bands (which at this stage were still in grey undercoat) could be fastened round to fix them properly.

Meanwhile, preparations were being made for the next step, which would be to fit the saddle tank and the cab. The tank had been stored on top of a container, and so it was lifted off from there with the crane, and the picture below shows it being lowered onto a trolley, so that it could be worked on.

Like the cab and the cladding sheets, the tank required sanding down to prepare the surface of the metal for painting, and the picture below shows one of our volunteers doing this.

Meanwhile, work continued on painting the cladding sheets, in their final livery of Brunswick Green. This was the standard colour used by the Hunslet Engine Company if a customer did not specify a particular livery, which evidently Brookes Ltd did not when they ordered the locomotive. In the picture below the cladding sheets have been painted, and the lower front portions of the cab are being fitted, still in red oxide primer.

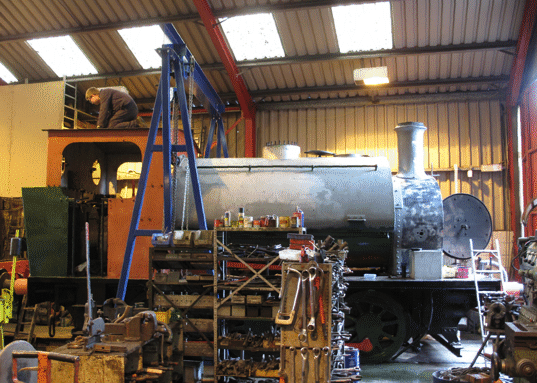

Once these parts had been securely bolted down to the footplate, then the top of the cab and the tank could be fitted, as in the picture below. All of a sudden, it is looking like a locomotive again - even though there is still a fair bit more work to do on it.

June 2017

A large part of this work concerns fitting the steam piping, and also the piping for the vacuum brake system. The photograph below shows the locomotive smokebox with most of this piping now in place, so that painting the smokebox could begin.

July & August 2017

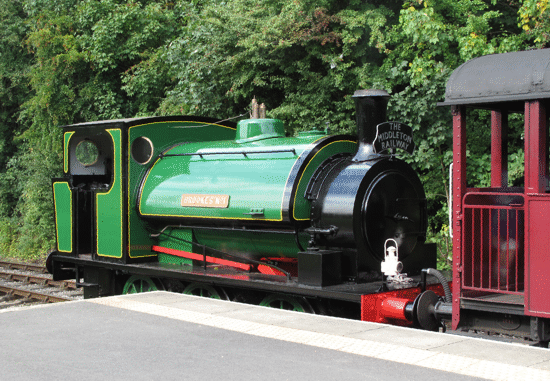

Painting continued into July, at which point a key decision had to be made: would we line out the locomotive, or leave it unlined? As far as we know it had not been lined out while it was operating at Brookes Ltd, although it did carry various other bits of decoration, including a large yellow circle on the back of the bunker which was intended to make it more easily visible. On the other hand, locomotives do look better if they are properly lined out, and so the decision was taken that we would line it out. This involved a lot of painstaking work, which ran on through the rest of July and into early August.

Once the paintwork was complete it was time for a test run. This was scheduled for 28th August (the Bank Holiday Monday), and so once the locomotive rostered for the services on that day (HC 1544 Slough Estates No. 3) had been prepared, Brookes No. 1 was pulled out of the workshop and lit up. For a test run steam is raised slowly, but after lunch there was enough steam pressure to decide that it would head the 2.40 train, with Slough Estates No. 3 at the rear. It ran beautifully, and the picture below shows it at Park Halt.

After some checks to make sure that no bearings were getting warm, the train returned to Moor Road, and it was decided that Brookes No. 1 would run the 3.20 and 4.00 trains on its own. So it did, and the picture below shows it at Park Halt, waiting to return to Moor Road with the 3.35 train.

Not surprisingly, a lot of the volunteers who had worked on it wanted to ride on it, and they were all impressed by how well it ran. "Like a sewing machine" said one; "a real Rolls Royce job" said another; while the driver's comment was "it just glided up the track".

This was not quite the end of the work, as a couple of minor points were identified that needed a little attention: a gasket had to be replaced, and there was at least one gland that needed a bit more packing immediately. But essentially the locomotive could now go into service, once crews had been trained to operate the lubricators, which are more elaborate than the ones on most of our other steam locomotives.

So the project had finished successfully. Do come and visit us to see the locomotive running.

Go back to the previous stage in this project.

Return to the overall description of this project.

More Information

Other pages about this project:

Other pages provide more information about:

Running Shed Phase 5 (Erect Framework)

As described in the page for the structure of the whole project, the Running Shed is being built in seven phases. The first three phases were all concerned with preparation for the actual construction work, and phase 4 was the construction of the foundations. These were completed just before our Victorian Gala on the weekend of 16th and 17th July 2016, and on the Monday morning Midbrook Buildings arrived on site to start erecting the framework of the building.

Monday

The first step was to sort out the uprights for the frames, and which ones would go where, and the picture below shows the various uprights laid out roughly into place on the foundation slabs.

The uprights for the frame laid out in their correct positions on the foundations.

Picture © Mark Calvert, 2016.

Then, after a lot of careful measuring, for each upright holes had to be drilled into the foundation slab, and then a bracket bolted into place on the slab, so that the upright could then be fixed to it. The picture below shows some of these brackets bolted into place, ready for the uprights to be fixed to them.

The foundation slab, showing the brackets for fixing some of the uprights for the framework.

Picture © Mark Calvert, 2016.

Tuesday

Work continued on setting out the brackets, drilling the holes for them and bolting them to the foundation slabs.

Wednesday

With all of the brackets fixed into place on the foundation slabs, then erection of the uprights could begin, and the picture below shows the first two uprights being erected.

The upright for the south-west corner of the building being erected, alongside another of the uprights for the west wall which is already in place.

Picture © Mark Calvert, 2016.

Later on in the day our crane was available to help, and the two pictures below (taken by our crane driver) show a further upright being lifted into place. Only one more to go to complete the west wall!

The sheeting rails are being fixed between this upright and the one to the south of it, to help provide stability to the whole line of uprights. Note the large brackets at the top of each upright, which are to attach the roof rafters. Note also the access platform (cherry-picker), which was not needed for this bit of the job, but was for fixing components higher up.

Fixing the sheeting rails to another upright.

Picture © David Hebden, 2016.

Another view of the sheeting rails being attached to the same pair of uprights.

Picture © David Hebden, 2016.

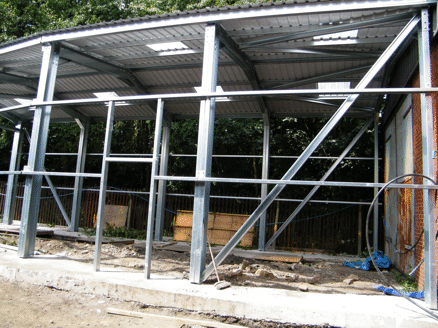

By mid afternoon the whole of the framework for the west wall had been erected, as shown in the picture below. This includes not only the uprights, but also the diagonal braces for the two end bays, which are the main components that provide stability for the whole assembly, along with the sheeting rails and the longitudinal roof girder. Work had started on the framework for the east wall, and the first of the roof rafters was in place.

The west wall framework, with the first of the roof arch girders in place.

Picture © David Hebden, 2016.

By the end of the day all of the uprights for the east wall had been erected too, and the longitudinal roof girders, as shown in the picture below. The next steps were then to install the rest of the roof rafters, and the diagonal braces and sheeting rails for the east wall.

The framework at the end of Wednesday.

Picture © Mark Calvert, 2016.

Thursday

Work started with the installation of the rest of the roof rafters, and the picture below shows two of them leaning up against the side of the Engine House building, ready to be lifted into place. The brackets on the top edges of the rafters are for attaching the sheeting rails for the roof, which run along the length of the building.

Roof rafters ready for installation.

Picture © Mark Calvert, 2016.

Once the rafters had been fitted, and the sheeting rails for the roof, then the next step was to start fitting the roof sheets. (OK, these are part of the cladding of the building rather than its framework, but that was the order that worked best for the people who were doing the erecting!). The picture below shows some of the roof sheets being fixed into place.

Roof sheets being installed. Note the access platform just visible by the corner of the roof.

Picture © Malcolm Johnson, 2016.

By the end of the afternoon the western half of the roof had been completed, as had the north-eastern quarter of it, just leaving the tapered pieces for the south-eastern quarter to be fitted, as shown in the two pictures below. Also the diagonal braces and most of the sheeting rails for the east wall had been fitted. The gap in the middle two bays had been left because the frame for the emergency exit door still had to be fitted.

Framework and part of the roof, at the end of Thursday.

Picture © Malcolm Johnson, 2016.

Framework and part of the roof, at the end of Thursday.

Picture © Malcolm Johnson, 2016.

Friday

Friday saw the remaining roof sheets fitted, and the remaining sheeting rails for the east wall, including the frame for the emergency exit door, as shown in the two pictures below.

The complete framework and roof, at the end of Friday.

Picture © Malcolm Johnson, 2016.

The complete framework and roof, at the end of Friday.

Picture © Malcolm Johnson, 2016.

So now that we had a complete frame with a roof on it, this phase had finished - we had said that we did not expect it to last longer than a week! Then work could start on the next phase, which was to construct the brickwork for the walls, and install the cladding sheets for them above the brickwork.

Go on to the next stage in this project.

Go back to the previous stage in this project.

Return to the overall description of this project.

More Information

Other pages about this project and the "Buy a Brick" appeal:

- An overview of the project and the appeal;

- The "Buy a Brick" appeal;

- The structure of the project;

- The progress with the project;

- The construction of the pit;

- Design and site preparation;

- Construction of the foundations;

- Construction of the walls;

- Fitting out;

- The opening ceremony.

Other pages provide more information about:

Running Shed Phase 6 (Construct Walls)

As described in the page for the structure of the whole project, the Running Shed is being built in seven phases. The first three phases were all concerned with preparation for the actual construction work, phase 4 was the construction of the foundations and the installation of the oil separator, and phase 5 was the erection of both the framework of the building, and the roof for it.

This was completed about a week before the end of July, and it had been expected that this phase would then follow on immediately with the installation of the cladding sheets for the walls. This in turn would be followed by us laying large numbers of bricks. After discussion with the contractors, however, it was agreed that a better sequence would be for us to start on laying the bricks, but before that there were one or two other minor jobs that needed to be done.

In particular, it was planned that the internal floor of the building on either side of the pit would eventually be stone ballast, and it would obviously be easier to get this into place before the brickwork was laid. Before that could be done, however, the spoil from constructing the foundations that was still inside the building needed to be moved out, using picks and shovels to excavate it, and then wheelbarrows and our JCB to move it away.

Removing spoil from the floor of the running shed, to make space for the ballast.

Picture © Tony Cowling, 2016.

Once this had been done, brick laying could start, and the picture below was taken on Saturday 20th August.

The first half-a-dozen courses of bricks have been laid.

Picture © Tony Cowling, 2016.

By the Sunday afternoon good progress was being made on this section of the wall, as shown in the picture below. The bricklayer is a professional who had volunteered to help, which is why the bricks are being laid far better and far more quickly than our amateur efforts could have achieved.

Bricklaying in progress.

Picture © Andrew Johnson, 2016.

The bricks had been stored in two of the open wagons, and were having to be unloaded: in the picture below this was from our 12-ton Middleton Colliery wagon. Also the blocks that form the inner skin of the walls had been delivered to the car park, and were having to be moved up into position in batches, ready to be used.

Bricks and blocks being unloaded and moved into position.

Picture © Andrew Johnson, 2016.

By the end of Sunday this section of the brickwork was almost complete, as shown in the picture below.

One section of the brickwork almost complete.

Picture © Mark Calvert, 2016.

A break was taken over the August Bank Holiday weekend, but the following weekend bricklaying continued on the west wall of the running shed, despite the weather. This required some shelter to be improvised, using a tarpaulin and some of the wooden covers that had been made for sections of the pit, and in the picture below the bricklayers can just be seen inside the shelter.

Two panels of the brickwork for the west wall of the running shed almost complete. Inside the shed mortar is being mixed for the blockwork for the inner skin of the wall.

Picture © Tony Cowling, 2016.

Here is a better view of the bricklayers at work: not ideal conditions!

On the left is the boundary fence, with the wooden covers resting on top of it, and the tarpaulin outside it. On the right is the brickwork for the west wall, almost up to the height of the sheeting rail.

Picture © Tony Cowling, 2016.

Meanwhile, more bricks were being unloaded from where they had been stored in the 13-ton mineral wagon, ready to be laid for the two southern panels of wall.

At the left-hand side of the picture is a water barrel, for mixing mortar, and then a pile of blocks for the inner skin of the walls. In the centre are the piles of bricks that are being unloaded from the wagon. To the right, over the pit, is the four-wheeled trolley that had been used to bring the next batch of blocks up from the car park.

Picture © Tony Cowling, 2016.

By the end of September the brickwork for the western wall was just about complete, and work was well underway on laying the blocks for the inner skin of this wall. The picture below shows this blockwork near to completion in mid-October. The section above the diagonal bracing will be filled in with lightweight foam blocks, so as not to put too much loading on this part of the frame.

The southern panel of blocks for the western wall being completed by one of our volunteers, who is checking to make sure it really is vertical.

Picture © Tony Cowling, 2016.

By the end of October this section of blockwork had been completed, and also the north-east section of wall had been completed: the picture below shows it with just the last course of brickwork about to be laid, while our volunteers had gone for a well-earned cup of tea. When they had laid this course there would still be a gap between the top of the brickwork and the sheeting rail, but this was intentional, as the sheeting extends down a little way below the bottom of the rail, and then there is flashing below it to fill in the gap. By contrast the inner blockwork does go right up to the level of the sheeting rail, as can be seen in the picture above.

The north-eastern panel of bricks just about complete.

Picture © Tony Cowling, 2016.

This meant that we just had the south-eastern section of the wall to build, but this was going to be the trickiest part, because it would incorporate all the engraved bricks that had been paid for through the "Buy a Brick" appeal. They had been engraved and were stacked in the Engine House, ready and waiting, as shown in the picture below. They had been carefully organised into rows to match the plan for where each one would go in the wall.

The engraved bricks laid out on the floor of the Engine House, in rows to match the plan for where each name would go.

Picture © Mark Calvert, 2016.

To make sure that they were laid properly we would definitely need real bricklayers. Fortunately, in mid-November another of the professional bricklayers who had offered to help us was able to spend a day on the job, and the picture below shows him finishing off the south-west corner of the brickwork, so that it lines up properly with the upright that will carry the door frame.

The south-western corner of the brickwork being finished off.

Picture © Mark Calvert, 2016.

Attention then turned to the south-eastern section of wall, where the first step was to lay six courses of plain brickwork. Then the courses of engraved bricks could be laid above those, according to the precise plan that had been worked out for which bricks would go where. Our chairman was invited to lay the first of these engraved bricks, as in the picture below.

Malcolm laying the first of the engraved bricks.

Picture © Mark Calvert, 2016.

As well as laying bricks, one other job which needed to be done at about this stage was to fill in the space between the two pits, once the drainage pipes which connect them had been laid in place. Since our cement mixer is only quite small, this involved mixing a number of loads of rough concrete, and the picture below shows one of the last of these being poured into place.

Concrete being poured for the wall separating the internal and external pits. The wooden shuttering is needed to ensure that, when the concrete has set, there will be an adequate flangeway for the track into the shed.

Picture © Tony Cowling, 2016.

Once all of the concrete had been poured it forms the floor of the doorway for the track into the shed, as illustrated in the picture below, which shows it having been levelled off in the wooden shuttering.

The completed concrete for the wall separating the internal and external pits, taken from the outside of the building. It now looks like the floor of a doorway.

Picture © Tony Cowling, 2016.

With this done there was just the last stage of the bricklaying to finish, which involved laying all of the engraved bricks in their planned positions and then finishing off the courses above them. This happened on the first Saturday in December, and the picture below shows the bricks all laid, and being pointed.

Another of the professional bricklayers who had offered to help us, pointing the engraved bricks in the south east wall. The bright red bricks are the ones engraved with the names of the players in the Hunslet Rugby League Team who played in the 1965 Challenge Cup Final against Wigan at Wembley.

Picture © Tony Cowling, 2016.

While the professional bricklayer was building the outer skin of the wall, our amateurs were laying the blockwork for the inner skin of it, as shown in the picture below.

Two of our volunteers laying the blockwork for the inner skin of the south east wall. The light was sufficiently poor to need flash, which has produced these curious reflections from hi-viz patches on overalls.

Picture © Tony Cowling, 2016.

The completion of this section of brickwork meant that everything was now ready for the rest of the wall cladding sheets to be fitted. This was done by the contractors in the last few days of December, but nobody seems to have been around with a camera to record it, and by the time we turned up on the following weekend the cladding was complete, as shown in the picture below.

The shed with the cladding complete and the personnel door installed. The pit is already in use for washing out the boiler of "Sir Berkeley".

Picture © Tony Cowling, 2017.

This effectively completed phase 6, although we still had to install the main doors at the south end of the shed. But that marked the start of the process of fitting out the shed, which was the final phase of the construction work.

Go on to the next stage in this project.

Go back to the previous stage in this project.

Return to the overall description of this project.

More Information

Other pages about this project and the "Buy a Brick" appeal:

- An overview of the project and the appeal;

- The "Buy a Brick" appeal;

- The structure of the project;

- The progress with the project;

- The construction of the pit;

- Design and site preparation;

- Construction of the foundations;

- Erection of the Framework;

- Fitting out;

- The opening ceremony.

Other pages provide more information about:

Subcategories

Projects

Projects and appeals.

Volunteering

For pages related to volunteering and membership