In June 2015 we ran an event to celebrate the 150th anniversary of the first locomotive to have been built by the Hunslet Engine Company Ltd. As part of our preparations for this, we restored the flatbed wagon that we had acquired from Hunslet's, starting in January 2015.

This restoration included the fitting of a through vacuum brake pipe, so that the wagon could be run as part of a passenger train. Originally, of course, the wagon had not had any vacuum brake fittings.

A page documenting this restoration formed part of the special web site that was created for that event. That site ceased to exist not long after the event, but we did not want to lose the record of this wagon restoration project, and so the material from it (including the logos that had been created specially for the event) has all been transferred to this page.

On the original site the pictures of the restoration work were laid out in rows of three, and appeared in that layout on any device. Here they have been re-arranged into rows of two, or a single column if you are viewing the page on a mobile phone, so as to give a better appearance.

|

|

|

Below is the photo gallery of the restoration of our ex-Hunslet works flatbed which was converted from an earlier wagon in 1951. Parts of it were found to date from 1897 and 1903!

Progress for the end of February : chassis well underway, brake gear overhauled and a sneak peek at the final livery!

April 22nd : The chassis lifted off its wheels to enable better access.

April 25th - May 10th : The wheels have been needled gunned down and painted up in red oxide. Also the brake gear painted up to black gloss.

May 24th - 31st : The frames were painted from red oxide up to black gloss/Brunswick green, a through pipe was fitted and brake hangers were sourced, as well as dolly hangers. The wooden planks were cut to size and offered up.

June 22nd : The wagon is now almost complete with the decking in place, brake gear finished and vacuum system complete. It is all looking very smart and the remaining jobs include axlebox lubrication (the original system used animal fat) and signwriting.

June 29th : This weekend some finishing touches were made to the paintwork, including picking out the brake handles with white ends. The signwriting has also begun as the picture below shows. This really is an exciting final step on the road to restoration.

The wagon chassis in the workshop

A close-up of a chassis angle, before cleaning

The chassis before painting, from above

An end view of the chassis, after needle-gunning

Original lettering on the solebar, revealed by the cleaning

A patch of original Hunslet green paint on the solebar, revealed by removal of a plate

A close-up of the chassis angles, after needle-gunning

A close-up of a brake-lever pin, before cleaning

Brakegear components on the workbench

Brakegear slotted levers on the workbench

Two bolts, one cleaned and the other waiting to be cleaned

A close-up of a brake-lever pin, after cleaning

Close-up of brake lever pin collar

Brakegear components after needle-gunning

A closer view of the wagon chassis

An end view of the chassis, partly primed

Preparing to llift the chassis off its wheels

Wheelsets over the pit, before painting

Wheelsets and chassis with the Engine House behind

A close-up of one wheel, before painting

A brake shoe in primer

Brake levers in primer, and brake shoes in black

The chassis outside, in primer

A close-up of one set of the W irons

The chassis outside the workshop

One wheelset in primer

The two vacuum pipe dollies drying

The chassis outside, in light grey undercoat

An end view of the chassis, mostly in grey undercoat

The chassis outside, with the water tower behind

The wheelsets in the workshop during painting

A wheel rim, showing the inscription "Millom Steel 10 11 97"

A close-up of a wheelrim, showing the date (1905)

An axle showing the forging date (1897)

A wheelset journal, with the boss in primer

The inside of a wheel boss, showing the inscription "1897 Dallam Forge"

Three painted brake levers

Parts of the brake gear after painting

An end view of parts of the brake gear after painting

One brake shoe, in black

The chassis outside, with the crane alongside it

An end view of the chassis, with the buffer beam in red undercoat

A wheelset, partly painted

The painted wheelsets in the workshop

The wheelsets in the workshop, with the vacuum brake pipe

The chassis outside, partly in green top coat

A close-up of a chassis solebar in green top coat

The chassis with the timber decking almost complete

The finished wagon in the workshop

A chassis solebar and the end of a bufferbeam, waiting for the last bits of brake gear to be fitted

One end of the finished wagon in the workshop

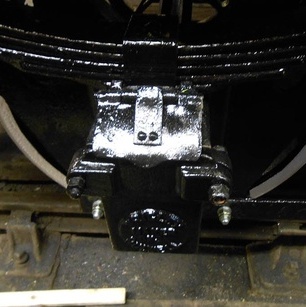

The underside of the chassis

A painted axlebox, showing the inscription "Wrigley Maker Bulwell"

A side view of the wagon

A spring and axlebox

A close-up of an axlebox

A vacuum brake pipe dolly

The finished lettering on the wagon